The Wilco Group of Companies has maintained its point spot thanks to its evolution in skills and its tool innovation

By Kelly Gray

From good beginnings, great things often grow. This is certainly the case with the Wilco Group of Companies, a Thunder Bay, Ontario-based leader in civil and landscape construction that has made a name for itself from the Lakehead to Vancouver Island.

Wilco was formed in 1981 when it concentrated on soft landscaping and environmental work. This focus grew from its roots as Wills’ Nursery and its affiliation with the Maat family of Fort William – as Thunder Bay was known back in the ’50s. It was the sons of Dirk Maat – Peter, Arthur, Rob and John – who got Wilco underway and began to spread the company’s branches across Western Canada.

“From a young age my father, Fred Cramer, worked for Dirk ‘Dick’ Maat. He worked hard for many years to earn shares in the company. In the mid-2000s, as the business grew, my father took over the Thunder Bay division and things took off from there,” said Wilco Group of Companies vice-president David Cramer. Today, Fred Cramer is president of the Wilco Contractors Superior division with his sons David and Richard managing operations as hands-on VPs who find themselves tackling some very challenging projects.

David reports that the last 10 years have seen the company grow exponentially and double in size. In 2008, Wilco started taking on structural work. “This is when we got into piling and took on larger civil projects and infrastructure work,” he said, remarking that in the Thunder Bay area, Wilco is among the few contractors that have a Ministry of Transport Ontario (MTO) qualification rating and can take on structural work.

Here, Wilco’s head of engineering, Travis Jaspers, mentions several projects that exemplify Wilco’s capacity. On a project on Ontario’s Jarvis River, the company had to adapt equipment to complete this specific job.

“The Jarvis River project saw us working with subcontractor

LTL Group where they turned a percussion hammer on its side to ram pipe into place. This was the first time that a pipe ramming project of this size had been used in the MTO northwest region,” Jaspers said, pointing to another example that had Wilco install 35-metre long precast box girders on a bridge project over the Sturgeon River in Geraldton, Ont.

“These were the longest box girders in the northwestern Ontario region at the time,” he said, adding that he gets a lot of job satisfaction from seeing his designs unfold from the drawing board to completion. “There are a lot of moving pieces to get projects completed and we have to shepherd each of those pieces as we move along. Given the work we do, many aspects present challenges, but our experience and skills allow us to take it all in stride.”

Building experience across a wide project base

Wilco Contractors Superior Inc. has utilized its knowledge learned from its earliest days to become a leader in the landscape and civil construction sector. “Our wide range of projects and scope of work allows us to take on a variety of site development projects, and to do it with the highest standards of efficiency and quality,” said David.

He also points to their ability to tackle large infrastructure projects. “Wilco has completed many MTO capital contracts,”

he said mentioning bridge replacements, bridge rehabilitations,

culvert replacements and other general road projects. Wilco also offers services to control erosion, an important component to their total infrastructure capability. David notes a few examples such as hydro-seeding, bonded-fibre-matrix and straw blankets, as well as environmental

rehabilitation projects and custom design site-specific erosion

control measures.

When it comes to fencing and guardrail projects, Wilco has been a leader in these installations throughout northwestern Ontario for almost 40 years. “We have built a strong reputation with the MTO, townships and other general contractors for delivering a quality product, safely and in a timely manner. We also offer a variety of fencing options from galvanized or vinyl chain link fences, to larger wildlife fencing solutions for highway projects,” David said.

New technology helps Wilco stay ahead of the curve

Jaspers mentions that part of what makes Wilco a go-to contractor is their large and growing equipment inventory. Indeed, Wilco has collected a wide range of rigs and gear that have allowed them to bid on some large projects. “We like to have the right tools for the job when they are needed. Our range of equipment is such that we can often take on work that others can’t,” he said pointing to Wilco’s new Berminghammer EML (Excavator Mounted Lead) 45 drop hammer as a great case-in-point.

“The EML 45 has opened a large window of opportunities for us as we move into a new year of proposals and projects,” he said.

According to Jaspers, the Ministry of Transport Ontario no longer allows vibratory equipment on some of its road projects. “Having a drop hammer with the capability of the EML 45 gives us the ability to compete for these jobs. We already have other hammers, but they can only do 20-foot sheet piles and have half the power of the new Berminghammer tool. For this reason, we went with a 10,000 lb. hammer, the heaviest hammer they make in the EML line.”

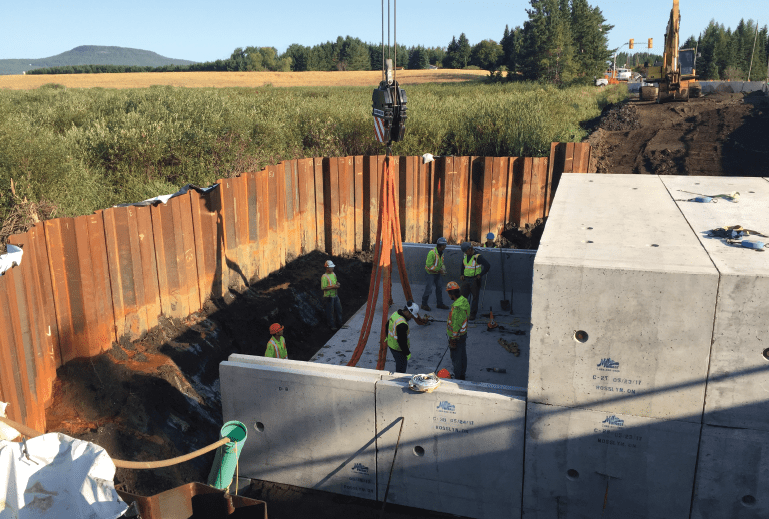

Jaspers suggests the EML 45 was ideal for the Gorge Creek project. “We had a different design for the project. With the new tool, we could pound 45-foot sheet piles and forget the tie backs that would have made the job more expensive. We were able to change the design and make the job less costly,” he said, remarking that the first day involved a bit of learning and then things took off.

“The EML 45 will help us with bids as we move into 2020. We have a project already on the boards for next year where we will likely make some changes to [the] design and use it. This winter, having this excavator-mounted hammer will give us an edge in the bidding process and will help us get those jobs.”

Berminghammer’s EML 45 impact hammer came on board at Wilco Superior this year. One of the most versatile hammers on the market today, Wilco has been using the device since the end of June, making them one of the first companies to take possession of this innovative tool.

The EML line-up offers pile driving lead systems for 30-ton, 45-ton and 60-ton excavators. These systems stand out thanks to their significant cost benefits over traditional fixed leads on smaller remote jobs of 10 to 20 piles.

“The gains are found in the significantly decreased costs to mobilize at the jobsite,” said David Zanchetta, P.Eng., sales and field services representative at Berminghammer Foundation Equipment. He points out that with most general contractors requiring an excavator for on-site work, they can attach an EML to the excavator prior to piling work. Then, when work is finished, contractors can detach the EML and continue using the excavator for its primary use. “This means piling contractors can mobilize the system with a single truckload and that saves money.”

What makes the EML 45 a good choice for piling contractors? “The rigs were designed with several design criteria; to deliver enough energy to drive piles specified for bridge piles, to be extremely mobile, quick to rig up and eliminate the need for crane mobilizations for small piling jobs. The uses of the system include bridge pier and abutments, soldier pile and lagging systems for roadway protection and piling location areas that are sensitive to vibration,” said Zanchetta.

Zanchetta notes that the EML 45 also has a longer drop than most systems. He says that with most systems offering a four-foot drop, the EML 45 can be scaled to feature a seven-foot height. “There is no wasted space. Operators can drive the maximum pile height using the maximum amount of energy to get the job done.”

Another huge benefit to the EML 45 is the side levelling feature. The system works with a swing of three degrees making it ideal for rugged terrain and challenging sites. “Simply, you don’t have to have the system perfectly level to get great performance,” Zanchetta said.

Jaspers points to the challenges of the job site that were conquered by the EML 45’s capabilities. “We were able to get the tool installed and ready to go after a short learning/training period, and then saw the performance greatly enhance the speed of the work. We have also been able to easily integrate this rig’s unique considerations into the morning safety meetings,” he said, adding that while maintenance and safety checklists for the EML 45 take a little bit longer each morning than with their other hammers, once it is ready, the speed of service makes up for those few minutes.

David Cramer notes that Wilco has been partnering with Berminghammer since Wilco’s early days and has appreciated Berminghammer’s ability to work with them to enhance their capabilities.

“We are looking forward to the coming year and our enhanced ability to bid on a wider range of jobs. In our line of work, having the right tools puts us ahead of the competition and that’s right where we want to be.”