We’ve all heard the phrase “go big or go home.” At its heart, it’s an expression that encourages us to be bold in whatever we do.

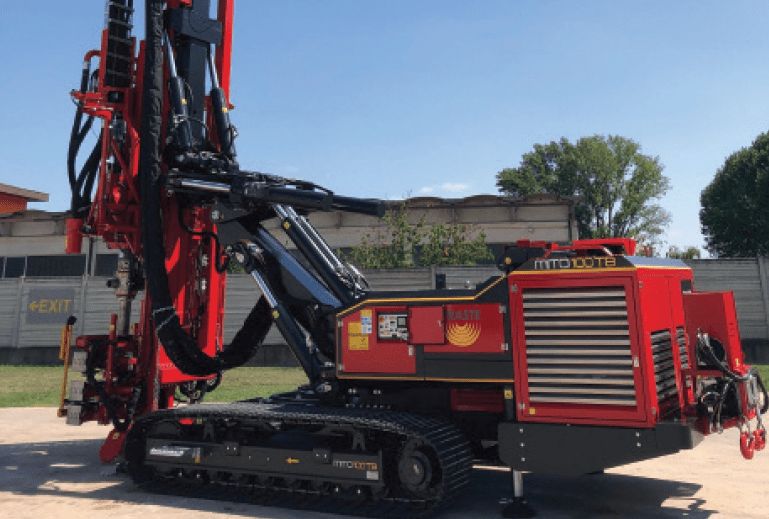

It’s an appropriate way to describe the philosophy of Italian manufacturer Fraste and its MITO 100 TB (the TB stands for tieback), the company’s latest, state-of-the-art drilling rig. It was unveiled for the first time at Bauma 2019 in Munich, Germany, the world’s largest construction machinery trade fair.

The MITO 100 TB has already made a big impression in Canada, which should come as no surprise considering it’s one of the biggest and strongest drilling rigs in its class currently available. Weighing between 39 and 40 tonnes with accessories, it’s a behemoth compared to similar drilling rigs that typically tip the scales between 26 and 30 tonnes.

Fraste sales manager Cristiano Marchioro says the MITO 100 TB is proof that bigger is sometimes better. Due to its size, the rig has a more stable base and produces far fewer vibrations or fluctuations than other smaller, comparable drilling rigs used for deep foundation work.

More stability

“That’s important because with these machines, the heavier they are the more stable they are,” Marchioro said. “The driller or operator knows that this machine will be very stable. If the machine is light, it will not be stable and the bore hole is not [stable] and can collapse or is not very straight. The machine must be very, very stable to do these kinds of big jobs.”

While the MITO 100 TB’s size is a big selling feature, it’s hardly the only one. According to Fraste, it’s the only machine of its size that offers a mast with full kinetic movement. It can accommodate two different mast sizes: a shorter version with a head travelling stroke of 8,000 mm and a longer edition that provides a travelling stroke of 11,000 mm. The shorter version is ideal for installing tiebacks in tough to access locations while the longer version is perfect for use with micropiles. The rig’s design allows either mast to be quickly swapped for the other in the field.

“It’s incredible,” Marchioro said. “It’s very well organized, very well engineered.”

Another interesting design feature of the MITO 100 TB is its one-of-a-kind carousel. It can hold up to nine drill pipes and nine casings of different diameters at once. Most other comparable rigs on the market can only accommodate eight. That can mean substantial time savings since the MITO 100 TB’s carousel doesn’t have to be loaded as frequently as other machines.

“That’s important because if you have three metres more (per load) you can do 27 metres without anybody touching any pipes or casings,” Marchioro said.

Like many of its competitors, the MITO 100 TB can be remote operated. That means the operator is much safer because they are not standing directly beside the rig to control it. In fact, it can be operated from a contained shelter when the elements are less than kind, so long as the operator has a clear view of the construction site.

Marchioro says Fraste’s latest offering to the construction industry serves two primary functions when it comes to deep foundation work: anchoring tiebacks and installing micropiles. In addition, it is well suited for drainage installations and jet grouting, a method of soil stabilization involving the injection of a stabilizing fluid (such as cement) into subsoil at a high pressure and velocity. Marchioro says the MITO 100 TB is ideal for use in the construction of foundations, basements and parkades, and reinforcing piling on exceptionally large jobsites.

Canadian connection

The MITO 100 TB has a definite Canadian connection. It was developed in response to inquiries from the company’s Quebec dealer (EFQ in Lachine, Que.), which had received numerous requests from customers about drilling rigs designed specifically for foundation work on large scale building sites. Fraste products are also available through MARL Technologies in Edmonton, Alta.

Although there had been little demand for a product like the MITO 100 TB in Europe, Marchioro says the Canadian market is a different story because transportation regulations here allow for easier transport of much larger and heavier equipment. “The market over there (in Canada) absolutely accepts the big dimensions for transport,” he said.

The drilling rig itself is manufactured “100 per cent” at Fraste’s plant in San Giorgio di Nogaro, located a short drive from Verona, Italy. The only component that is manufactured elsewhere is the MITO 100 TB’s engine, which is produced by Caterpillar at its U.S. manufacturing plant. It typically takes about two weeks to ship a unit by boat from Genoa, Italy, to Halifax, N.S.

It features both single and two-headed designs with conventional, two-speed rotary heads at the top of the mast along with a sonic or vibro head at the bottom. Options for the MITO 100 TB include a hydraulic hammer, winch and a wire line winch. The rotational head stroke clocks in at 7,500 mm and it produces a maximum torque of 3,400 dekanewton-metres at a top speed of 190 revolutions per minute.

The MITO 100 TB has been manufactured to meet all North American safety standards. That includes a safety push button on both the machine and the remote control that allows an operator to immediately shut the rig down.

Minimizing environmental impacts

Marchioro says Fraste has made every effort to ensure the unit also meets the latest North American environmental standards. Its low-emissions engine is in line with current Tier 4 emissions specifications and it uses a synthetic oil produced by Panolin in Switzerland. Since the oil is biodegradable, there is virtually no environmental impact should an oil leak occur. Compare that to one litre of standard oil that can pollute up to one million litres of water.

As it’s still a relatively new machine, Fraste has gone out of its way to ensure that operators are fully aware of every aspect of the MITO 100 TB and how it handles. Its Canadian dealers provide two weeks of extensive training to customers compared to the one week of training that is standard with most of the company’s drilling rigs.

To date, two of the MITO 100 TB units are in use in Canada, and a third is in the process of being shipped here. Marchioro says the preliminary feedback on the machine has been extremely positive and he expects demand to increase substantially as word of it spreads in the Canadian construction industry.

“I think so. It is so good for the type of work they have to do normally in Quebec, and I believe the rest of the country. I think when more people know about the machine that there will be more demand. I have already seen that from experience.”