Black Diamond Drilling Tools Canada is now setting up shop in Ontario, bringing to Canada its high-quality hammer and bit products, as well as a well-deserved reputation for exemplary service known around the world

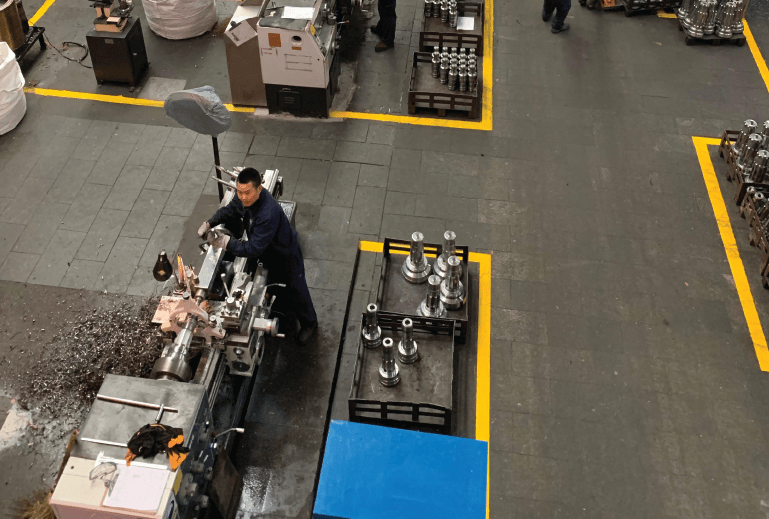

Black Diamond Drilling Tools Canada is the Canadian arm of China-based Changsha Heijingang Industrial Co., Ltd. Founded in 1999 by owner Riping Yang, Changsha Heijingang Industrial is a well-known, privately operated enterprise located in Lei Feng, Wangcheng that employs more than 800 people at its massive 1.5 million square foot production plant.

The company’s various facilities are available for research and development, as well as manufacturing and testing for its approximately 1,000 different sets of rock drilling and pneumatic tools.

Changsha Heijingang Industrial currently manufactures more than 20,000 hammers and over a quarter-million bits annually for a number of industries, such as mining, quarrying, geotechnical, water wells and production drilling. Although Black Diamond has only recently been building its name and brand awareness here in Canada, the company’s product offerings are popular around the world, where clients such as Australia’s mining giant, Rio Tinto, value Black Diamond and its parent company for its deep-rooted commitment to quality and service.

“Changsha Heijingang Industrial – and Black Diamond – is known around the world for its use of high quality raw materials, advanced production technology and strict testing methods to produce excellent products with good performance characteristics,” said Gerry Lafontaine, Canadian sales manager at Black Diamond Canada. “We are one of the biggest complete manufacturers in the world of down-the-hole and reverse circulation hammers, from three inches in size all the way up to the very biggest of hammers.”

By manufacturing its own product from raw materials and dealing directly with its customers, Black Diamond is able to eliminate several links in its supply chain and, because of this, the company is able to typically offer a better-than-average price when compared to its competitors. Black Diamond also endeavours to work closely alongside and collaboratively with its customers to provide the correct product for the job at hand. The Black Diamond team relies heavily upon its extensive industry knowledge and experience when changing the operational parameters of its products in order to meet the exact performance requirements of its customers and does so with a minimum turnaround.

“Currently, our manufacturing lead time is just 20 days from the time when we decide on a solution and then, it’s just the delivery,” said Lafontaine. “We really just want to put our best foot forward here in Canada and invite industry to try us out and see how our service and products stack up against whatever they might already be using.”

Black Diamond provides a superior level of support for its customers and has the ability to access the expertise of more than 100 engineers located in both Australia and China to explicitly tailor product solutions that are specific to its clients’ many variable needs. What’s more, once Black Diamond determines the proper solution going forward, the company will then locally warehouse a three-month inventory of that product to ensure quick delivery directly to the jobsite.

Serving the Great White North

Black Diamond seeks to further improve upon its Canadian presence with the opening of its new, approximately 3,000 square foot storefront and warehouse located in Sudbury, Ont. The first shipping containers of product manufactured in China and Australia arrived at the new store in mid-February, which allows the company to hold a large amount of stock on the shelf to meet its customers’ immediate needs. Looking ahead, Black Diamond is also close to opening a 20,000 square foot warehouse in Mississauga, Ont., that will act as its Canadian distribution hub. By having warehouses and stock located within Canada, Black Diamond will now become even more responsive to its customers and eliminate the current three-month delay incurred when shipping by ocean crate.

“Canada’s mining industry is really striking right now and, by opening up here in Sudbury – and soon in Mississauga – the lead time on your order once we are set up will be tremendously reduced,” said Lafontaine. “So if one of our customers comes through the store and says they need a six-inch hammer with a six-and-a-half-inch bit, we’ll have it all on our shelves, ready to be loaded onto the delivery truck and off to that customer the very next day.”

In the long-term, the hope is that once Black Diamond becomes firmly established in Sudbury and Mississauga, the company will further extend its reach across Canada and into the U.S. However, the company is currently quite satisfied in taking a steady and measured approach to expansion in order to avoid the treacherous pitfalls of growing too fast, too soon.

Changing minds

There are a number of challenges that still face Black Diamond in bringing its brand to Canada, primarily centred on changing the traditional North American mindset towards “Made in China” products. While many still believe that the quality of steel coming from China is inferior to the steel of Western markets, this couldn’t be farther from the truth in regard to a company like Black Diamond and its parent company. Changsha Heijingang Industrial has put no end of effort into fine-tuning its manufacturing processes and procuring steel internationally, from places like the U.S. and Sweden, to ensure that its rock drilling and pneumatic tools perform as well as, if not better, than similar tools now being used here in Canada.

With this in mind, Black Diamond is currently conducting tests with prospective Canadian customers in order to showcase the high quality and superior performance of its tools; and the response from industry has been very positive. The results from the testing done so far clearly demonstrate Black Diamond’s timing to be better and more responsive than many similar products, as well as the excellent durability of the bits themselves, which often outperform the competition.

“Once the potential customer takes the initiative and says that they will do some testing, then it is really just the matter of them seeing our products in action,” said Lafontaine. “We will ask that they record their own timing of the penetration rate and measure the performance so that they can see for themselves what they have on their hands. And then they can see that there is more to Black Diamond than just better pricing; they also have the opportunity to receive a high quality, high performance product.”

Not just a company, but a family

The motto that helps guide Changsha Heijingang Industrial in everything it does is simple: A cheerful life is a long life. This saying drives a company-wide culture that is further fostered by the owners, Yang and his family; one which Black Diamond Canada works to incorporate into its day-to-day operations, whether that is in how it deals with its customers or in how it approaches safety.

“The first time I visited the manufacturing plant in China, I was fully expecting what we here in North America imagine a Chinese factory to be. But what I discovered was the complete opposite,” said Lafontaine. “Everyone – from the person cleaning the facility, all the way up to the management – is extremely welcoming and it’s like a big family. This attitude is reflected in the workmanship and innovation of the products we make.”

Black Diamond’s Sudbury branch will be celebrating its official opening later this spring when the owners will be coming out to welcome the new location into the fold.