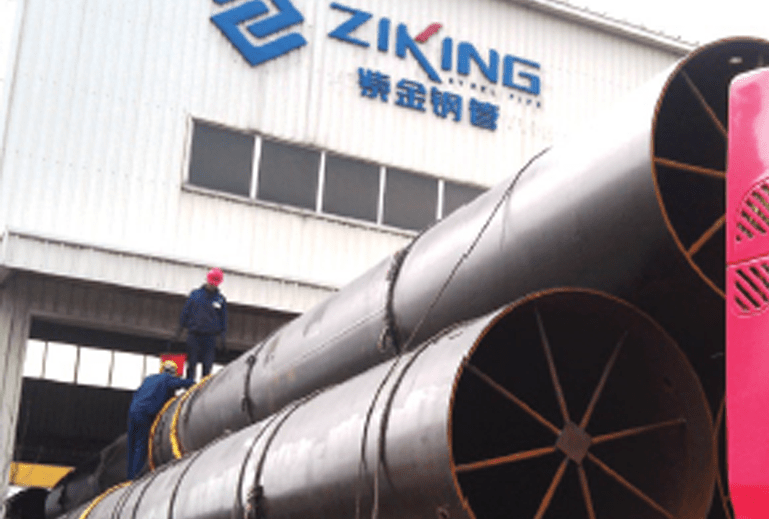

Hefei Ziking Steel Pipe’s presence in Canada allows for more direct interaction with customers

By Pat Rediger

Hefei Ziking Steel Pipe is a company that works hard to play to its strengths. The company, formed in 2004, operates a Longitudinal Submerge Arc Welding (LSAW) and rolled steel pipe mill in East China.

The company has access to a vast supply of steel plates and is strategically located riverside, which allows barge transportation in low rate freight and access to the break bulk loading Ports of Shanghai and nearby.

Perhaps one of the company’s biggest strengths, however, is its presence in Canada.

Shortly after the mill was originally put into production. the company discovered that there was heavy competition in China. Looking outward, the company identified a need for LSAW pipes in the North American market as the deep foundation industry was entering a new era of design for large diameter, thick wall, straight weld seam steel pipes. With no pipe mills in North america capable of producing these pipes, Hefei saw an opportunity.

In 2008, the company opened up an office in Vancouver to handle its North American sales. There are currently three people working out of the Vancouver office and remote sales staff in Houston and los Angeles.

“We are the only Chinese steel pipe mill that has its own sales office and staff in North America,” said Shenwei Wang, the lead sales executive in North America. “There are similar companies in China, a number of which are similar to us or larger that us, but they do not have their own sales people in Canada and their documentation is not in the standard North American format.

“An elite English speaking team of executives and engineers at the China mill ensures a deepter understanding of the detailed requriements and standards of global clients, and have a [good] perspective of market potential. Since making the move to North America, we have made more sales for several pipe projects. We’re [also] proud to be members of the National Association of Steel Pipe Distributors and the Pile Driving Contractors Association.”

As Wang explains, Hefei’s presence in Canada allows for more direct interaction with customers. When beginning a new project for a client, Wang says the company starts by getting a thorough understanding of the desig and drawing specifications of the pipes needed for the project, evaluating the whole cost and concluding the purchase order detail.

After submitting the tech documentation and recieving the client’s approval, Hefei then procures the exact steel plates required and begins production of the steel pipes. The pipes are run through numerous tests to ensure they meet the specifications. The company then ensures the pipes are prepared for long distance transportation with protective coating and ships them on a vessel with trained workers.

“We’re able to unerstand what our customers wnat and work to fulfull their expectations,” said Wang. “Many of our customers are interested in purchasing the exact amount of hosing they need, not more. One of our biggest advatages is that we can deliver these orders to the exact specifications given to us by the customers.”

One of Hefei’s specialities is forging and shipping oversize mono piles of up to 262 feet (80 metres) in full length, cerified and pre-coated with U.S. material. Thse piles have been used in various marine terminal constructions across North America.

Hefei was involved in the expansion of the Nanaimo Port Cruise Ship Facility in the Port of Nanaimo. Cruise ships had been accessing tha harbour since 2002, but there was no permanent facility to discharge passengers, who had to take a shuttle boat to reach the shore. A noe floating concrete pier was built that was moored to a number of pilings. Hefei provided piles for that project. The company has also provided meterial to Alberta’s evergy industry for various projects.

In the U.S., Hefei has played a part in the reconstruction of the coastal infrastructure of New Orleans following Hurrican Katrina in 2005. Hurrican Katrina saw high winds, high water and erosive waves pound the coastline, which caused sifnificant damage to piers, beach houses, roads and numerous residences; many were destroyed outright. With many marine terminals needing steel piple, Hefei’s services have been in demand.

Wang says the company understands the process.

“Contractors of pile driving realy love to get finished mono pile on site without further processing, splicing or coating,” he said. “If this is achieved, the save big when it comes to cost, time and complexity of handling.”

Recently, Hefei’s 80-metre long mono pile will supply a Canadian federal strategic energy project. As Wang says, this was a monumental moment for the company.

“Our current year-long supply project at the federal level shows that we’re receiving more recognition from stakeholders of major projects,” said Wang. “We are positioned to be te first priority for upcoming projects similar to this one when it comes to supplying stell pipe piles. This will help us make further progress when it comes to being a prominent supplier in North America.”