With more than 30 years of experience and 90 different models of piling machines such as the MC, CH, GEO, and CX lines, Comacchio has sold more than 4,000 units across the world in 100 countries working in the field of geotechnics, deep foundations, ground improvement, tunnelling, water well drilling, geothermal and exploration.

Comacchio always focuses on customer orientation, training and support for their products, tailor-made to suit specific needs and new technology investment. In addition, all Comacchio products and team members emphasize building qualified technicians, continuing customer support with spare parts and services, new advancements in drilling operations, and compact and efficient design.

Geotechnical drilling rigs have become more compact, efficient and with lower operational costs. Comacchio introduced the CH series multipurpose self-erecting drilling rigs to work with bored piles with the Kelly system, continuous flight auger (CFA) piles, large diameter micropiles, displacement piles and soil mixing.

The CH 150 is part of the CH series with five multipurpose piling rig models (including the CH 150) and one dedicated CFA rig. These machines can be supplied both in the CPD version (cylinder pull-down) and WPD version (winch pull-down). All of them are totally self-erecting and can be transported as one piece with the Kelly mounted, except for the CH 650, which requires some minor disassembly for transport.

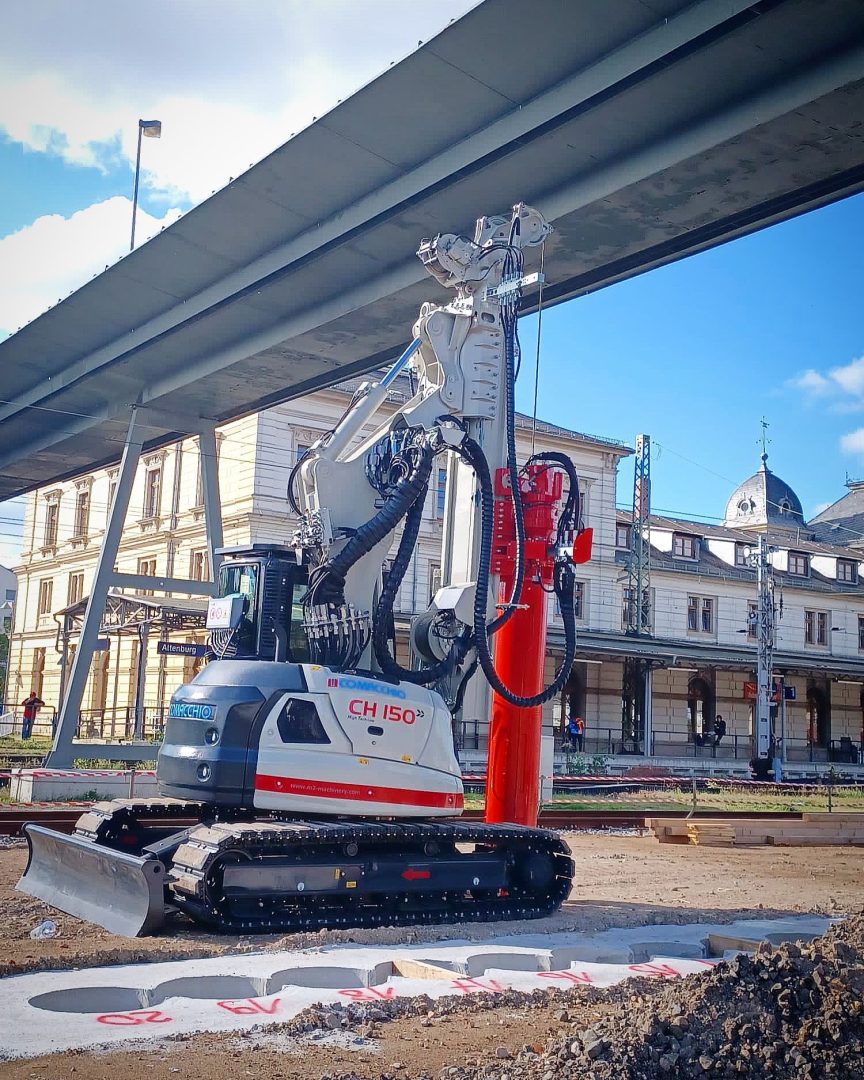

A growing number of projects involve building and maintaining small and medium-sized infrastructures in urban areas with a dense population. Foundation contractors are required to work in small, difficult-to-access spaces, such as on slopes, under bridges, adjacent roads or near railway lines. With the increasing demand for fast construction, project schedules are short, require short mobilization time for project tools, difficult access to terrain and low maintenance costs.

To meet that need, Comacchio presented the CH 150 with a compact size, lightweight design and innovative technology that adapts to different applications and flexible working conditions. The CH 150 drilling rig was presented first during the 2021 GeoFluid exhibition in Italy, and had great success with current and future customers by selling some units immediately in Italy, Germany, and Israel.

Furthermore, due to market trends and demand, Comacchio plans to introduce the CH 150 at the upcoming CONEXPO-CON/AGG for the North and South American market.

The CH 150 is exceptionally compact, agile and versatile compared to traditional rigs. The rig is only 7 feet 7 inches wide and 24 feet long, and weighs approximately 33,000 pounds with a rotary head and Kelly bar included. Its compact size and lightweight design allow for trouble-free transport of the machine in one load with the rotary head and Kelly bar installed and with possible ancillaries without oversize/overload permits.

The rig is completely autonomous for rigging and de-rigging and can easily be offloaded from transport vehicles. There are no pre-requirements for its operation and it is immediately ready for site operation. It’s also ideally suited for operating in low headroom conditions, typically under bridges, viaducts or beneath existing structures.

Despite its compact size, the CH 150 incorporates the same technology associated with larger models, such as the CCS software, developed by their experienced in-house technicians.

Moreover, the CH 150 adapts to different applications and working conditions. This machine will provide the conventional mid-sized excavator base carrier with a modular drilling mast and a multipurpose rotary head. The mast is mounted on the excavator boom on the side of the cab. The long reach of the boom, combined with the mast rotation capabilities, ensures that the CH 150 can cover a wide range of mast positionings, precise positioning, efficient adjustments and provide the required rigidity.

Due to its nature and flexibility, the CH 150 maintains lower operational, ownership, and maintenance costs and reduces unproductive time. It is designed as a multipurpose unit that can perform various construction methodologies from the same rig, including the Kelly system, CFA piles and even micropile installation.

It is also much easier to use for operators, especially for those who are already trained to work on excavators: the advanced in-cab controls integrated with the joysticks and supported by sensor technology provided by Comacchio allow the operator to manoeuvre the machine easily and manage all functions in tight spaces in an effortless and precise way.

Despite its compact size, the CH 150 incorporates the same technology associated with larger models, such as the Comacchio Control System (CCS) software, developed by their experienced in-house technicians. It allows complete control of all machine functions and drilling parameters, including fault diagnostics, construction depth measuring, r.p.m. measuring, vertical alignment, hoist and lowering limit switches on main and service winch ropes, crowd pressure setting, spinoff and shaker tool dump systems. In addition, the visibility offered by the fully glazed cabin is excellent without compromising safety and increasing performance output.

The rotary head on the machine has a compact and lightweight design, and can transmit up to 32,268 pound-force feet torque. It can be used in multiple interactive gears and in “auto speed management” mode, thus ensuring the optimal r.p.m. and torque balance depending on the drilling task. The rotary head adapts to different drilling methodologies programmed by the CCS system. The rig’s modular design ensures that conversion can be performed easily, in a short time and at a low cost.

The machine can easily transform from the standard Kelly configuration to the auger cast piles and CFA piles with a simple conversion kit. Comacchio has also brought the most modern technologies into the base carrier’s hydraulic system, optimizing it for this application to ensure maximum productivity and greater energy efficiency.

The CCS system electronically controls the diesel engine, thus allowing the hydraulic system to acquire the total available power from the engine and maximize productivity. In addition, the cooling system of the base excavator hydraulics has been enhanced to cope with demanding environmental conditions along with the intensive use typical of a foundation construction site, even in the most demanding environmental conditions.

Geotechnical construction application and project spotlight

The CH 150 can be used for dry excavation of cased and uncased bored piles with the Kelly system, reaching a maximum depth of 88 feet 7 inches. Pile diameters can range from 2 feet 6 inches to 3 feet 3 inches depending on the Kelly bar type used. The modular length of the mast allows the use of Kelly bars of up to nine elements and 11 feet 6 inches in length, with a diameter of up to 16.5 inches. The installation of casings can be done using a driver installed on the rotary head up to a maximum diameter of 2 feet 6 inches.

In CFA configuration, the machine offers over 37,000 pounds of extraction force and can operate with augers up to a maximum diameter of 2 feet 6 inches. The maximum achievable depth of CFA piles is 39 feet 1 inch, which is done using a bespoke extension. The required stability is guaranteed using the extendable undercarriage (7 feet 7 inches to 9 feet 7 inches), which is included as part of the standard configuration of the machine. This means the CH 150 can cover the most requested auger sizes (usually from 1 foot to 2.5 feet) in CFA configuration.

This installation process is virtually vibration free, making it ideal for working near existing buildings or environmentally sensitive areas. The machine can be applied for seismic strengthening and retrofitting applications in earthquake zones. It can be used for foundation upgrades, strengthening existing structures, refurbishment works, and temporary and permanent piling applications for tension and compression loading.

It is well suited to multiple ground conditions as it can be equipped with various tooling (auger, bucket, core barrel), including casing.

Working on the A14 Bologna-Bari-Taranto highway, the second main north-south backbone of Italy, the CH 150 is the best tool for maintaining many viaducts along this motorway. In addition to refurbishing and reinforcing these structures, viaducts must be upgraded for anti-seismic performance in a region of Italy known for its earthquake activity.

One project involved the seismic reinforcement of the Giustina viaduct, approximately 400 metres (1,315 feet) long, and the simultaneous reinforcement of the foundations of all piers and abutments.

The project envisioned expanding the existing structures on which the piers rest to increase the number of piles supporting the foundations’ base. As a result, six piles of 1,000 millimetres (3.3 feet) in diameter were constructed beneath the piers for both carriageways. The lowest piers required piles of 20 metres (66 feet) deep, while the piles beneath the highest piers were 25 metres (82 feet) deep.

Characteristically, the soil within this area is typically made up of consolidated clays with sand and silt layers and intermittent pockets of aggregates. The drilling and grouting needed to be performed underneath the viaduct, with a clearance ranging from a minimum of 7 metres (23 feet) to 19 metres (62 feet) below the deck beam. The CH 150, with its compact size and manoeuvrability, proved to be the ideal solution for this project.

Commacchio presented the CH 150 with a compact size, lightweight design and innovative technology that adapts to different applications and flexible working conditions.

The Kelly setup was used to perform pile installation to the maximum diameter achievable, to a depth of 20 to 25 metres (66 to 82 feet), which is quite an achievement for a machine within this weight category considering limited access and low headroom. The CH 150 proved to be more than capable of meeting the needs of this task, with an average production output of four piles per day, with production only slowing when particularly stony layers were encountered.

Overall, the CH 150 has proven to be a game changer with its compact size, low maintenance cost, conversion kits and ease of operation in many geotechnical construction applications.

Moreover, Comacchio is always welcoming technical and innovative feedback for their products, advanced training to their technicians and promises to deliver high-end products to their stakeholders.