Ervin Bata hoped when he left Canada for Australia four years ago he would return home one day. In fact, he and his wife had already spoke about returning when the time was right to begin raising a family.

Bata returned to Canadian soil a little more than a year later and it had everything to do with bringing a new entity into the world – just not the kind you might be expecting.

Soon after arriving in Australia in 2014, Bata was introduced to Stephen Ainge, the director of Hard Metals Australia, by a mutual friend. One thing led to another and he was hired a short time later as the company’s manager of drilling products. Bata already had extensive experience in the drilling and metal fabrication sectors, having worked for the likes of Hyduke Energy Services and Western Drilling Tools prior to moving to Australia.

Soon after being hired, Bata began travelling around the world to help promote Hard Metal’s directional drilling products to international customers. Following a strong reception at the Global Petroleum Show in Calgary, Ainge suggested setting up a subsidiary here in Canada with Bata serving as the company’s general manager.

In October 2015, Hardmetals Canada Inc., was launched. The business specializes in promoting the company’s signature PDC Wombat Hole Opener to the Canadian horizontal directional drilling (HDD) market as well as providing associated services and products to the general drilling market. Reflecting on the Global Petroleum Show (GPS), Bata said, “We had a patented item that people hadn’t seen here before in the directional drilling side of things. When we displayed it at the GPS we sold it on the spot.”

It was a new concept and Bata says there was no direct competition for the product at the time. In fact, there were only two or three companies servicing all of Western Canada for HDD back then. The company determined there was another related market it needed to explore – the construction and foundation drilling industry, including the supply of auger teeth and screw piles.

Many screw pile companies will produce products for themselves because they are big enough and have the time and effort to put into it, but nobody was really taking care of the little guys at the time. Companies that generally had only three or four jobs a month and didn’t have much experience with certain sizes of auger drilling often didn’t know who to turn to for help.

“That’s where we thought there was an opportunity to expand and do something new and help people out,” Bata said.

One of the priorities of Hardmetals Canada has been promoting the company’s proprietary line of drill bits and tools. This has been done with a particular focus on innovative products which were developed back in Australia but had yet to be introduced to North America. One of those products was the HeliBit. It was designed to give up to 30 per cent improved integrity and faster drilling rates in a variety of ground conditions through a special patented geometry of presentation of the cutters.

Another standout product the company offers is the Wombat hole opener, which has provided the company with a solid foothold here in Canada. Company officials hail it as a significant step forward in hole opening technology when it comes to HDD. It features field replaceable cutting segments, cutter segments for different conditions, variable hole diameter on the same cutter body and is suited for both forward or back reaming. It’s the equivalent of a Swiss army knife.

“We saw there was no competition in that area (hole opening),” Bata said of the Wombat, which was designed in Australia. “With most hole openers you usually just have one size. If you are drilling a 16-inch hole you use a 16-inch hole opener. Now you are able to go from 12 inches to 24 and you’re saving tons of money, space and time.

“It was actually designed for hard rock formations in Australia. We lucked out that there was already a market for it here in Canada, especially in Alberta where companies have to contend with the Canadian Rockies. It’s worked out pretty well for us. It’s really taken off here (in Canada).”

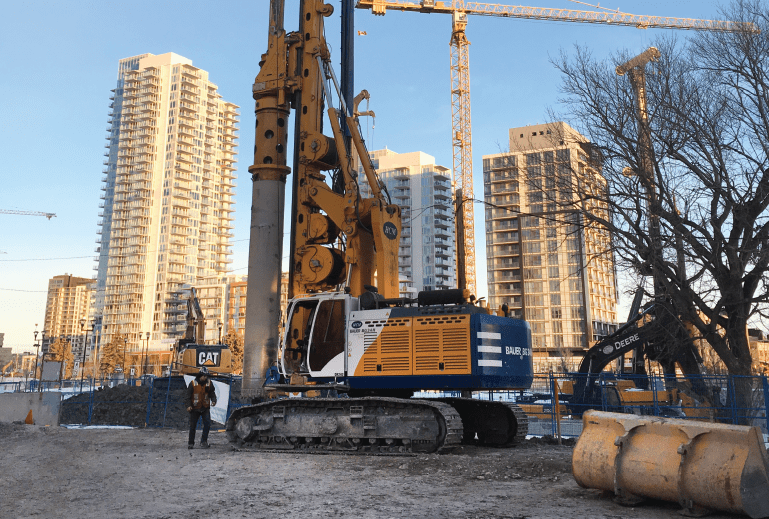

That’s been especially true in Bata’s hometown. Hardmetals Canada has been involved in a number of deep foundation projects including the Arris mixed-use tower project in Calgary’s East Village area where it teamed up with HCM Contractors Inc. The company has recently begun expanding its footprint here in Canada. It recently started up 3 Way Industries Inc., a sister company to Hardmetals, a metal machining shop that specializes in API threads and thread repairs. It also offers custom cutting, drilling and finishing services and offers specialized piles and building augers.

Bata says having ready access to machining services next door to Hardmetals’ Calgary offices means issues can be addressed much quicker now rather than always having to collaborate with the folks at other machine shops. It also allows the company to better address the particular needs of the Canadian market and manufacture more items in-house.

“It’s helped tremendously,” Bata said of the machining operation, which is a partnership between Hard Metals Australia, its Canadian counterpart and Michael Gottli, a machining expert and former plant manager.

Bata acknowledges that his company experienced some early growing pains in Canada. Initiatively, it began offering the complete line of products available in Australia but quickly learned the needs of the Canadian marketplace were substantially different. For example, many of the drill teeth that are used in Australia aren’t suitable for the conditions here in Canada, which meant they had to be redesigned or remanufactured.

“There were definitely some growing pains,” Bata said, “It took about a solid year for us to do all the R&D and sort of learn everything we needed to know.”

To date, most of Hardmetals Canada’s business has been in Alberta, B.C. and Saskatchewan, but is hoping to extend its reach into Eastern Canada in the near future. It was a sponsor of the ASDC golf tournament in Toronto this past August, which Bata says helped the company raise its profile in that market. “We’re looking to break into that market,” he said. “We had pretty good feedback from people who were interested in our product.”

What began essentially as a one-man operation, Hardmetals Canada and 3 Way Industries now employs a dozen full-time employees and recently added a night shift. Although Bata has been pleased with the growth of his company, he is far from satisfied and sees plenty of room for growth.

“Am I satisfied? No. You can always do better. That’s the attitude and mentality you’ve got to have. We’ve got to find ways to improve. If you are happy with where you are at you might be in the wrong business,” he said.

“The key thing with us is service. We’re always there, we’ll always pick up the phone. I get customers telling me, ‘If I get one phone call in jail it will be to you guys because I know you pick up.’ The thing is, you have customers for about a month or two until they get to know you. After that, you have friends and that’s what we have.”