It is a trouble spot in the western Austria road network: the Bludenz-Bürs junction of the A14 motorway. There are frequent traffic jams and delays due to congestion.

To avoid dangerous tailbacks on the motorway, by the end of 2021 ASFiNAG – a publicly owned Austrian corporation which plans, finances, builds, maintains and collects tolls for the Austrian autobahns – is to build a large roundabout with two bridges over the A14, as well as two new connections to regional roads, also with a roundabout and water protection facility.

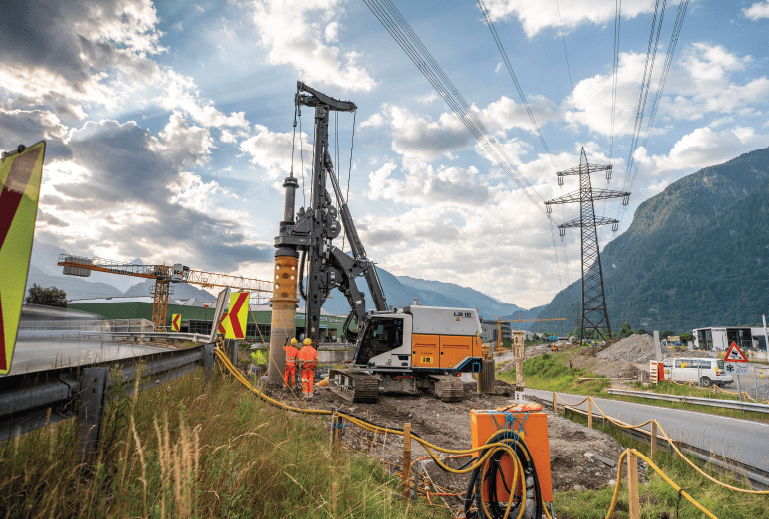

The local company i+R is carrying out the deep foundation work on the west side and will use the world’s first drill rig on the market with “Local Zero Emission.” The LB 16 unplugged, recently launched by Liebherr, has an electro-hydraulic drive concept and can also be used cable-free thanks to the battery, hence “unplugged.”

The challenge

Certainly aware of corporate responsibility for the environment and society, the alternative drive concept has been well received by the customer. “Sustainability in the construction industry is not a foreign concept, but common practice for ASFiNAG. Innovative developments like the world’s first drilling rig with zero emissions show that also on ASFiNAG construction sites there is enough room for environmentally-friendly construction practices,” said Andreas Fromm, managing director of ASFiNAG Bau Management GmbH.

The challenges for i+R are the narrow construction site itself, as well as the restricted working height. The pile foundations must be placed directly under a power line. Therefore, the drill rig is designed as a low head with a shorter lead. During the project i+R is installing 148 piles and drilling 1,742 metres total into the ground. Approximately 1,200 cubic metres of cement are being poured. The piles vary between 10 and 14 metres in depth and have a diameter of 900 millimetres. Due to the restricted working height, two metre casing pipes have to be used and the reinforcement cages have to be inserted in sections. The machine achieves approximately two piles per day.

The benefits

The absence of a combustion engine has two particular advantages: the LB 16 unplugged produces no local exhaust emissions and also generates considerably less noise. “You don’t have to shout all the time. You can talk normally and your colleague hears, even when standing further away. Otherwise, when the engines are running at full power, they are very loud and you always have to raise your voice, which is a burden in itself. You also don’t hear little things in the surrounding area, which you do now during ongoing site work,” said foreman Sebastian Timpe. Therefore, the quieter environment is also a safety-relevant aspect in regular construction site operations.

The machine has no restrictions in terms of performance and application compared with the conventional version. The battery is designed to last one working day (10 hours) and can be charged easily overnight using a standard construction site electric supply (32 A, 63 A).

Local zero emission

Sometimes the cement for this project is delivered by the Liebherr concrete mixer ETM 905 with electric drum drive. In normal operation the battery capacity is sufficient for the entire working day. As a plug-in hybrid, the battery can be charged during the journey or externally via a plug at a concrete mixing plant. i+R also uses an electric compact excavator. Thus, deep foundation work on a construction site is carried out for the first time using almost exclusively electrically driven machines. Therefore, the best possible combination of customer benefit, environmental compatibility and efficiency is achieved. Estimated over one year, approximately 35,000 litres of diesel fuel can be saved and more than 92 tonnes of CO2 emissions can be avoided.

“The construction site at Bludenz-Bürs is a win-win situation for everyone: enhanced safety and fewer traffic jams for the local Vorarlberg people, and environmentally-friendly use of construction machines on the currently largest ASFiNAG construction site in Vorarlberg,” said Fromm.

See the LB 16 unplugged in action, and visit www.liebherr.com for more information.