Since Neil Montgomery purchased Vibe Drive Technologies three years ago, he has improved the quality of his vibratory pile drivers from the ground-up. He has streamlined the manufacturing processes while remaining intensely focused on turning out fine quality products at a fair price and backed by excellent service.

Prior to heading up operations at Vibe Drive, which is based in central Alberta, Montgomery spent 40 years in the oil and gas industry including the last 15 years spent specializing in new product design and engineering. During this time, he has authored and co-authored several patents.

Most recently, he managed a $7 million “skunk works” project in which he recruited a world-renown physicist from the Royal Institute in London, England, along with an engineering team with diverse technical expertise to design ground-breaking “artificial lift” technology involving pneumatics, computerized algorithms and powerful electromagnetics focused on reducing carbon footprints in the oil and gas industry.

Montgomery said he was looking for a “new challenge” when a chance opportunity led him to purchase Vibe Drive Technologies. “I bought Vibe Drive, dropped in some healthy working capital and took the helm of this company with great future potential,” he said. He noted that pretty much all aspects of manufacturing were done in-house, but after an in-depth review of the manufacturing processes, he quickly made changes and instituted a process of lean manufacturing.

“Vibe Drive outsourced the laser cutting, CNC machining, welding and powder coating, but kept in-house the engineering oversight, warehousing of product, custom assembly, crating, shipping, customs, brokerage, invoicing and of course, not the least, client relations,” he said. “My days of managing a large staff are over, in-house staff levels are down and productivity and client satisfaction are very high.”

Montgomery has also guided his employees to reimagine the company’s products. Since the leadership shift, the team at Vibe Drive has re-engineered some of the company’s well-known models for skid steers and created some new designs for small excavators.

Vibe Drive models

The company’s vibratory drivers are designed specifically to attach to small excavators and skid steers. As it relates to skid steer models, the company’s 120-SS and 120-LS post and pile drive models can be purchased as a centre mount and/or a full left shift mount for those who wish to drive posts or piles down a line with relative ease. The 240 Series post and pile drivers are designed for larger model skid steers and can safely drive small piles up to 18 feet in height.

The company’s newest model, which Montgomery said is generating plenty of interest, is the 120-MX post and pile driver, which easily attaches to any smaller-type excavator.

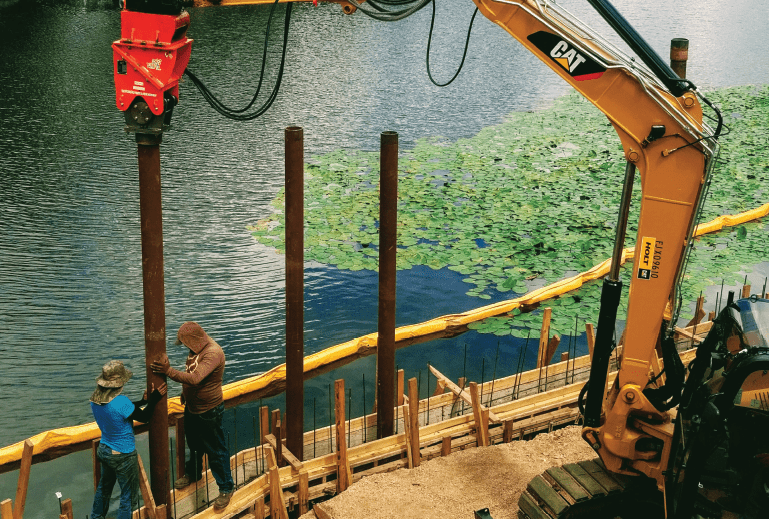

“Currently we supply vibes for 5-15 ton excavators, but we do have a few clients with excavators in the 22-ton range using our vibes to drive piles 8-inch and under. Finally, we have a design that hangs from a picker-boom truck allowing convenient access to areas otherwise hard-to-reach.” He adds that certain models of the vibe drivers can be ordered with an array of optional attachments that will “quick-change” into any one of several other handy tools.

“We can now convert from a post/pile driver to a concrete breaker or a hoe pack (tamper) in moments. The operator conceivably could be driving piles at 10 a.m. and ten minutes later could be ‘breaking concrete’ or tamping a ditch. These vibe drivers are very popular attachments and quite reasonably priced. This multi-tool system is designed for either skid steer or excavator models.”

Montgomery said the company designs and outfits its products to perform well with very little maintenance required. “As an example, the vibes require high-speed hydraulic motors to work properly,” he said. “We could, of course, buy motors from the Far East (at much reduced costs) that would probably last through the warranty period, but we instead buy expensive ultra-high-end motors from North America and Europe, which can be several thousands of dollars more each. When we say our product quality is the finest, we do mean it.”

When it comes to driving piles, Montgomery said that Vibe Drive’s focus is on small diameter pipe. The company concentrates on driving steel from two-, three-, four-, six- and up to eight-inch pipe, with examples including high security fences, slope protection, retaining walls, solar piles, highway cable and barrier support posts. The units are small, but they certainly “pack a big punch.” He said that a client recently purchased a MX (excavator) unit for vibing in 7-inch casing (to refusal) for retaining walls on the Colorado River. In terms of marketing the product, Montgomery said that Vibe Drive has determined that in most cases selling factory direct is currently the most appropriate business model.

“It does help in keeping our costs down and makes us a more attractive option for clients,” he said. “By overseeing customs, brokerage and the selection of transport alliances, we can load product on a Friday afternoon and have it in Texas by Monday or Tuesday next [week].”

Vibe Drive’s products are marketed through its website (vibedrivetech.com), direct mail, various dealer associations and word-of-mouth. To date, the company has sold its products throughout Canada and the U.S. (including Alaska) and Puerto Rico.