The John Hart Generating Station just outside the city of Campbell River, B.C., has been helping to power Vancouver Island for more than 70 years. To ensure the continued delivery of clean, reliable energy for many more years to come, the timeworn facility will soon be replaced by a brand-new generating station slated to begin operation later this year.

Encompassing 100 hectares inside Elk Falls Provincial Park, the John Hart facility is one of three hydroelectric generating stations on the Campbell River system that together supply about 11 per cent of Vancouver Island’s total power needs.

Stephen Watson, communications lead for the John Hart project for BC Hydro, notes the total construction bill will end up close to $1.1 billion. “It’s on schedule and on budget to finish in the fall of this year, so we’re near the finish line,” he said. “It’s been an amazing project.”

Construction on the John Hart project began in the spring of 2014. At the peak of construction last summer, there were about 500 people working on the site. According to Watson, safety has always top priority on the jobsite. By the beginning of spring, the project was closing in on three million person hours of work without a lost-time accident, he says. The project contractor is InPower BC, a consortium led by SNC-Lavalin and which includes Aecon Group, Frontier-Kemper Constructors, General Electric and Hatfield Environmental.

Fraser River Pile & Dredge (FRPD) of New Westminster, B.C., was sub-contracted to do the deep foundation work for the project.

There are four main components to the John Hart project:

- Construction of the replacement generating station located about 500 metres up the penstock corridor from the existing facility

- Replacement of three 1.8-kilometre-long pipelines with a single, 2.1-kilometre-long tunnel

- Construction of a new water intake at the John Hart Spillway Dam

- Construction of a new water bypass facility within the powerhouse

Cofferdam construction

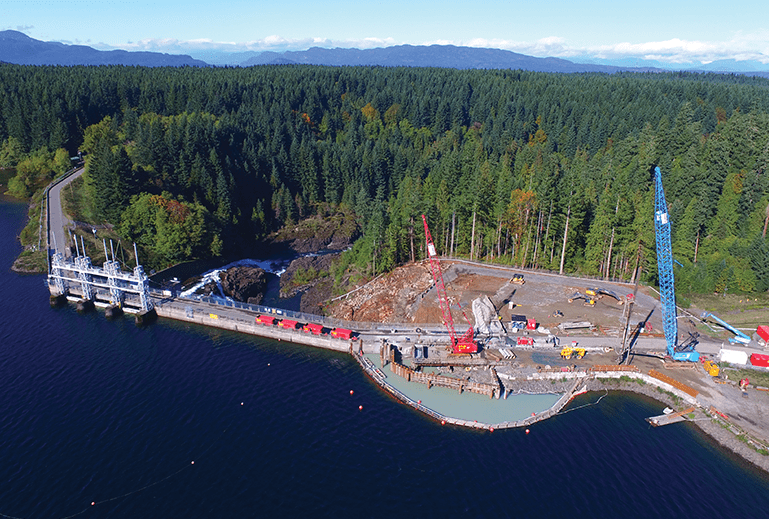

Because most of the new facilities have been moved underground and built in basalt bedrock, the only aspect of the project involving deep foundation work was a cofferdam erected in John Hart Reservoir, the man-made lake that feeds the John Hart powerhouse, but is also the City of Campbell River’s main water supply.

The steel cofferdam was built by FRPD in 2015 to support excavation work for the new water intake. It was installed beside a 24-metre-deep, double silt curtain that enabled FRPD to drill piles without fear of impacting water quality for both fish and area residents. “There was a fair amount of turbidity or cloudiness within the water captured in the work area, but nothing went in to the wider reservoir,” Watson said. “Turbidity within the reservoir was a significant project risk [but] we did not have one water quality issue.”

According to Sarah Clark, president and CEO of FRDP, the company utilized 75 interlocking 914-millimetre pipe piles for the cofferdam, which was 58 metres long and created a work area of 420 square metres between it and the John Hart dam.

Clark notes the cofferdam was constructed from land utilizing Manitowoc 3900W and 4100W crawler cranes equipped with reverse circulation, rotary percussion drill heads and semi-fixed lead systems. “The interlocking pipe piles…were drilled into five metres of basalt with rotary percussion technology that utilized a custom frame for alignment,” Clark said.

FRPD returned in 2017 to remove the cofferdam and also to support blasting operations necessary for construction of the new water intake for the John Hart Generating Station. According to Clark, a Liebherr 883 crawler crane and an American Piledriving Equipment 200 vibratory hammer were used to remove the cofferdam. FRPD also utilized the Liebherr 883 during this time to clamshell dredge the blast rock from the intake structure, says Clark.

FRPD supplied most of the equipment for its work on the project and utilized numerous suppliers, including many local businesses. Among the notable suppliers, Clark says, were Pinnacle Drilling Products, which provided ring bits and specialized drill tooling, and Wadit, which supplied the piling interlock sealant for the cofferdam.

Clark says her company was grateful for the opportunity to work with on a “legacy project” such as this. “The John Hart project was a great opportunity for FRPD to show how adaptable and conscientious our team is. Taking care of the city’s reservoir was a top priority and the crew delivered a great end result while taking care each step of the way,” said Clark.

Reasons for the project

According to Watson, the driving forces behind the John Hart project were:

- Reducing seismic risk

- Increasing reliability

- Protecting the downstream fish habitat

Because the existing facility and pipelines are unlikely to withstand even a moderate earthquake, the new generating station has been built to modern-day seismic standards. “With this new facility being underground in bedrock, it’s seismically much more robust and stronger,” Watson said.

The old generating station equipment is also in poor condition, with a less-than-optimal electrical output that’s been declining for years. The new facility will be more efficient and more reliable. According to Watson, the new generating station will generate 132 megawatts, enough to power roughly 80,000 homes compared to about 74,000 homes with the old system.

“Overall, we’re getting nearly a 10 per cent increase in power output using the same amount of water flow,” Watson said. “It’s just more modern equipment.”

The project also features a number of long-term environmental benefits. If the new generating station stops working for any reason, the new water bypass facility will allow water to continue to flow, preserving the downstream habitat for fish. According to Watson, that’s particularly important in an area like Campbell River, which is widely regarded as “the salmon capital of the world.”

In addition, the land where three pipelines used to be is being re-forested, reducing BC Hydro’s environmental footprint in the area. “We are working adjacent to a provincial park and there are certainly high standards and guidelines for environmental protection, so we made sure that we have a really good environmental management plan,” Watson said.

Part of that plan involved taking steps to protect at-risk wildlife species that turned up on the jobsite, such as Pacific sideband snails and Northern red-legged frogs. “We have removed and returned to the wetland about 150 red-legged frogs from the entire project site since we started, and so those are the kinds of nuances that have made it successful,” Watson said.