Dean Construction Company Ltd. was incorporated 71 years ago in 1947, but this Windsor, Ontario-based company can trace its roots back to 1926 when co-founder Americo Dean Sr., an Italian immigrant, ventured into the construction industry.

Today, the company is in its third generation of family ownership – with executive advisor Americo Dean Jr., president Brooks Dean, vice president Marc Dean and general superintendent Erik Dean – as it continues to take on projects across Ontario.

Historically, Dean Construction was involved in sewer and watermain construction, highway building, aggregate production and trucking, as well operating as a general contractor on municipal buildings. Dean has regularly been an early adopter of new technologies (crawler-drawn scrapers, diesel pile hammers, helical piers, elevating barges, among others), all of which have enhanced its long-term competitiveness.

“We also pride ourselves in developing and constructing one-off pieces of equipment to overcome challenges on specific projects,” said Marc Dean.

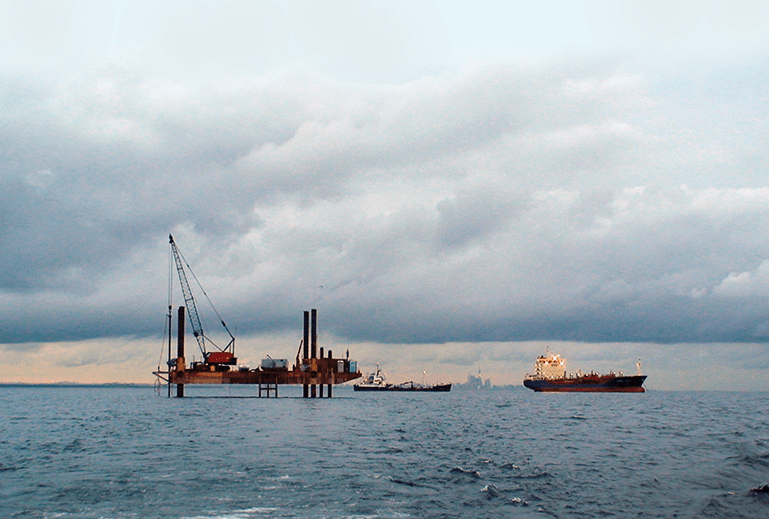

The company’s main office is in Windsor, Ont., but it also keeps a complete kit of floating plant on Lake Ontario to improve its competitiveness in that region. With a business scope that encompasses everything from federal dredging projects to municipal water treatment plant intakes and outfalls in marine environments to environmental remediation projects to many forms of deep foundations, Dean said, “Our wide range of construction activities and knowledgeable crews have allowed us to shift from one field of construction to another as markets dictate; although most of our projects have some marine element, even if the work is performed from shore.”

The Windsor-Detroit Truck Ferry Project represents many of Dean Construction’s capacities compressed into one small site.

“The Windsor-Detroit Truck Ferry Project included large diameter pipe piles driven from barges, which were cleaned out to bedrock using a custom-made fly-drill, grouted tensioned and tested rock anchors, small diameter pipe piles, steel sheet piling, tremie concrete placement into custom-built steel, left-in-place concrete forms, steel ramps and related fabrications, as well as dredging, pre-treating, rehandling, trucking and disposal of contaminated sediments and armour stone shore protection,” said Dean. “All activities on the project were done in compliance within strict Ministry of Transport Ontario guidelines under Dean’s MTO Core Quality Control Program.”

Strong reputation

Dean Construction is one of the largest marine contracting and deep foundation specialists in the Great Lakes region. As concern grows over the poor quality of the Great Lakes ecosystem and the need to reduce pollution, contain or remove contaminated sediment and remediate the environment, the company remains committed in helping to protect and restore environmentally sensitive wetlands, fish habitats and recreational areas through the construction of fish spawning areas, artificial reefs, waterfowl habitat and environmentally conscious shoreline protection.

“We are continually purchasing, upgrading and building new equipment to improve the quality and efficiency of our work,” said Dean. “We are fully staffed and equipped to perform virtually all types of pile driving, preboring, subaqueous drilling, caisson, cofferdam, dredging and barging work.”

When asked what the biggest changes have been in the pile driving industry over the past 20 years, Dean says the increased number of viable deep foundation options in use today. “The new foundation systems have been tested and field-verified. Engineers now have the information to use these systems to make deep foundations more economical,” he said. “Dean’s ability to install many of these systems, and the fact that we are not locked into specific technologies or suppliers, give[s] us the flexibility to propose a variety of alternatives to owners and engineers.”

However, above all else, Dean Construction would not be the success it is today without its strong safety initiatives. “We’re currently pursuing our COR certification,” said Dean. “We have created a position and hired a full-time safety manager to facilitate this. In addition to legislated safety requirements, we also incorporate eCompliance and ISNetworld to manage and track our safety efforts and documentation online. We also tap into local and industry-specific safety resources, such as the Industrial Education Cooperative.”

Areas of expertise

Over the past 50 years, Dean Construction has driven countless piles and drilled numerous caissons in all types of ground to support buildings, bridges and heavy equipment.

“We have also sunk shafts and built large cofferdams in difficult soils to permit the safe construction of water and sewage treatment plants, pumping stations as well as the deep foundations required for many industrial projects,” said Dean.

The company owns and operates many types of conventional equipment, including diesel impact hammers, caisson drills and all the associated equipment. It also has ready access to a wide variety of specialized equipment through its contacts in the industry across North America.

“Our team has built recreational marinas for many public and private clients around the Great Lakes,” said Dean. “The scope of our work typically includes the construction of breakwaters, shore walls, dredging, boat ramps, mooring piles, fixed and/or floating docks, utilities, fueling stations and sewage pump-outs.” Past projects have included:

- Port Dover, Ontario Harbour Improvement

- Windsor Riverfront Retention Treatment Basin

- Sterling Marine Fuel Site Dock Upgrade

- Burloak Water Intake

- Farr Island Re-grading

- Shell Dock Emergency Repairs

Great Canadian Flag project

One recent project that really stands out in Dean Construction’s portfolio was its involvement in the Great Canadian Flag project. Five years in making, the project finally came to fruition on May 20, 2017, when the 18 metre by 9 metre Canadian flag – atop a 45-metre-high flag pole (weighing more than 5,800 kilograms) – was erected at the foot of Ouellette Avenue along Windsor’s waterfront.

This project was the culmination of a plan that first went before City Council in 2012. However, City Council board member Mary Baruth emphasized that the idea was born nearly 40 years ago, originating with Windsorite Thomas McDade in 1980. Funding for this approximately $350,000 project came from both private donors and the Federal Government to commemorate Canada’s 150th anniversary.

“Dean’s involvement with the Great Canadian Flag stemmed from our relationship with a long-time client who was spearheading the project,” said Dean. “We were one of the contractors that donated time, labour and equipment. The helical piers installed were 4.5-inch diameter, with 16-inch diameter helices and an average depth of about 40 feet. It was not a large or complex piece of work, but the public’s positive association of Dean with the project made it very rewarding.”

What’s next?

As for what the future holds, Dean Construction’s star continues to shine bright. When asked what is in the foreseeable future, Dean said, “Our medium-term plans include increasing our involvement in larger, longer-term projects through increased involvement with owners and design/construction teams, increasing our capacity to perform deep foundations in urban environments and geographic expansion. We are also constantly looking for heavy construction personnel to develop and grow within our organization.”

The company invested heavily to enlarge and enhance its marine facility on the Detroit River in LaSalle, Ont. “By consolidating our operations at one location, we have improved our efficiency and primed ourselves for the long-term expansion of business.”

No doubt Americo Dean Sr. would be proud.