For decades, the Trans-Canada Highway in the Kicking Horse Canyon near Golden, B.C., was considered a dangerous stretch of highway. The narrow, two-lane highway caused traffic to condense in tight areas along a scenic corridor, inevitably leading to accidents.

Construction work began three years ago to convert this area into a modern four-lane highway. The final phase was completed about a year ago and involved realigning curves, mitigating rock fall and avalanche hazards and adding wildlife fencing.

Part of this project was providing the groundwork for massive bridge structures that span the gaps and it’s deep down in the ground where Luke Sheppard recalls that Western Drilling Tools made a difference.

“It was a huge project and we were involved in the micropile section of it,” he explained. “The micropiles were the chosen method for the abutments of the bridges, largely due to the difficult access on the cliff side. We helped provide the tools and equipment, and the support for the drilling company that drilled all those piles.”

Sheppard is the general manager of Calgary-based Western Drilling Tools, which designs and builds down-the-hole (DTH) drilling tools for clients who are often looking for technical solutions for their projects. The company offers a wide variety of services ranging from engineering and design, machining, welding and inspection.

Western Drilling Tools manufactures and supplies drilling tools for construction drilling applications requiring micropiling, anchoring, jet grouting and more. Its comprehensive line of construction drilling tools are designed for various drilling methods including reverse circulation, rotary and DTH hammer drilling.

“Micropiles have become a very big focus of our company,” explained Sheppard. “They’re a type of technology that offers a solution in complex situations where a large diameter rig isn’t possible or ideal.”

He adds that the company works with its clients to address various issues with micropiles, such as the need for a small drill along a steep embankment, small platforms, in urban settings where there is limited room to manoeuvre large equipment, or to conduct work in an area that requires minimum ground disturbance.

There is also growing demand for jet grouting solutions, where the client wants to reinforce the ground rather than digging it out.

Typically, a client will come to Western Drilling Tools with a specific project in mind. They often want to know what their options are for different types of materials, various sizes and different grades. The first step is usually getting an understanding from the client about the project and then educating them on the options that are available, and how flexible the design can be. The team at Western Drilling Tools can go back and forth with the client as they investigate various solutions.

“We have a large lathe with capacity to thread up to 14-inch-diameter pipe. There are very few of these types of machines around, which gives us an edge for casing jobs, in particular.”

– Luke Sheppard, Western Drilling Tools

“Sometimes an engineer from a customer will create a requirement that is not necessarily available in the marketplace. For example, they may have designed the foundation to use pipe size or grade that isn’t available locally. So, we often provide the support to help guide them through the options that are available and try to help find the most suitable and cost-effective product,” said Sheppard.

That might mean reviewing the different sizes, grades, thread design, lengths of the pipe being used, how are they going to connect the pipe to the rig, and so on. The company’s staff review all aspects of the project from beginning to end to make sure that no stone is left unturned in finding the best solution.

They work with the client to understand the scope of the job and what’s needed, so nothing is missed. “Once tooling arrives to site and is assembled, they can’t stop because one thing is missing or wasn’t noticed,” said Sheppard. “Every minute the drill isn’t turning is costing the contractor big money.”

Once the solution arrives, Sheppard says the company begins to procure the necessary materials, the engineering team designs the job, and then it’s a matter of working with the client to ensure that everything proceeds as expected. It’s the front-end work before a project begins that ensures its success at the end.

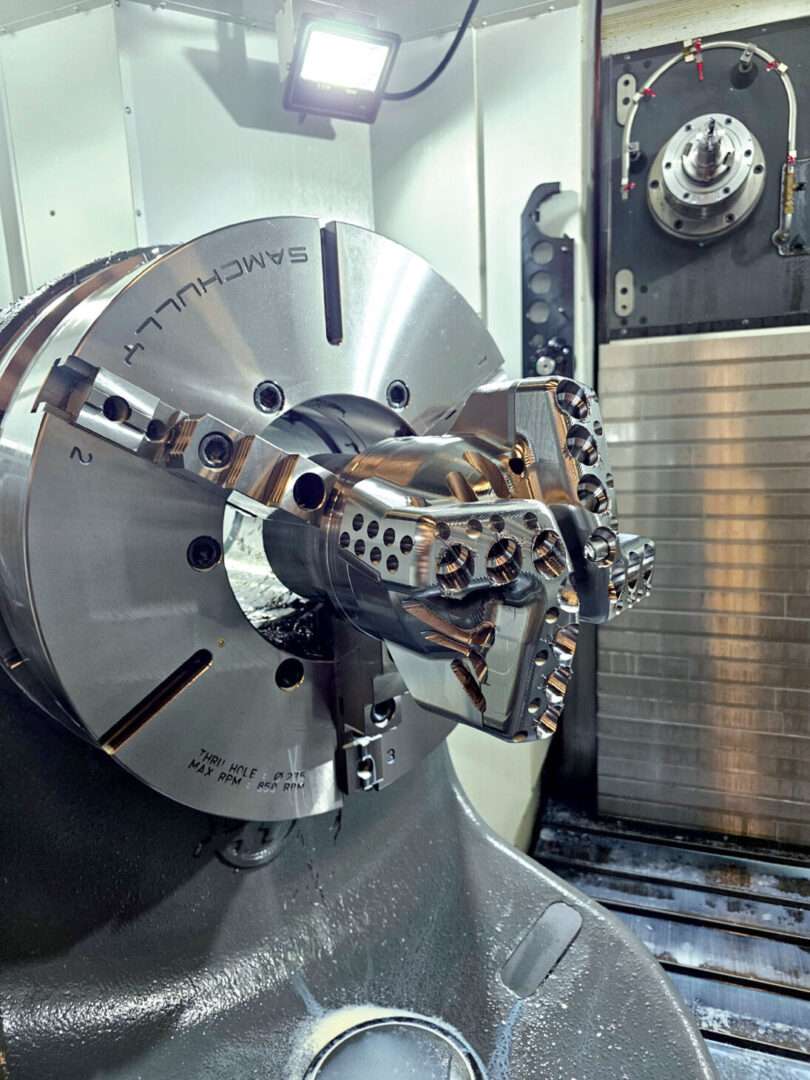

One of the competitive advantages for Western Drilling Tools is its 40,000 sq. ft. shop on 2.5 acres that is filled with the latest equipment managed by experienced personnel. To assist with fast turnaround on jobs, a large inventory of raw and finished products is kept in stock, from pipe to drill bits to hammers. The shop contains 10,000 lb. cranes, an impressive fleet of CNC machines, a large welding department and an in-house engineering team.

“We have a large lathe with capacity to thread up to 14-inch-diameter pipe,” said Sheppard. “There are very few of these types of machines around, which gives us an edge for casing jobs, in particular. We have many other machines of various sizes, as well as new ones coming this summer that will increase the size of our fleet and our capacity. It’s a matter of not just having the right machines for the type of work that is required in the industry, but also having multiple ones to get the job done twice as fast, and great machinists.”

He adds the company also employs a second shift, which helps to expedite projects for clients that require quick turnarounds.

Western Drilling Tools began in 2004 by Constantin Burca, who remains the owner and president. Burca also created other successful ventures that he eventually sold. He is noted for his inventions in drilling technology and holds several patents.

“As a large, privately-owned and operated company, we prioritize clear communication and collaboration with our clients to ensure we find the right solution, the first time,” said Sheppard.

“From prototype to production, we know establishing a relationship with our clients and clearly understanding their unique needs are of the utmost importance. With our machining expertise and your industry knowledge – together we will create the solution you need.”