As the demands placed on construction sites intensify, finding ways to improve schedules and decrease costs have become increasingly critical. As a strong proponent of the observational method, Nadir Ansari was early to recognize the need for a high-quality monitoring service for the heavy civil construction industry to provide feedback on systems performance,

allow proactive correction when unacceptable movements occur and mitigate risks on construction sites. The president of Isherwood Geostructural Engineers, Ansari formed Monir Precision Monitoring, based in Mississauga, Ont., as Isherwood’s sister company in 2002.

Monir’s general manager, Samantha Ford, has been at the company since its formation. Ford, who began her career as a field technician for Isherwood in 2001 after studying geotechnical investigation and geology in college, has extensive experience in the field as a geological technician, certified engineering technician and construction project manager, and is uniquely qualified to lead Monir’s team.

“Designing and building excavation support systems or making structural changes to a building [requires] many assumptions and predictions,” she said. “Verifying these assumptions during construction is critical to a project’s success. The engineers determine where they have geotechnical questions and we provide answers to those questions with our industry expertise and state-of-the-art monitoring systems.”

For a typical excavation, inclino-meters, total station monitoring and other instruments as needed are used to accurately measure shoring movements. Beyond the walls of an open excavation, Monir may monitor neighbouring structures including buildings, utilities and subway tunnels to ensure operations are safe to continue. Developers and builders may also request pre- and post-construction condition surveys and vibration monitoring of adjacent properties to insure against possible legal claims from neighbouring owners.

Allowing for timely adjustments during construction

Monir works closely with consultants and builders on-site, remaining agile and receptive to new ideas with advancing construction methods, Ford says. As an International Organization for Standardization registered organ-ization, the company has developed policies and procedures for all aspects of its work.

“Anything from the telephone safety check-in system, to the details of how to set up a site’s total station control network, to standardizing all our documentation,” said Ford.

Also, since variations or inconsistencies in data reporting can easily result in misinterpretation of the readings and lead to inappropriate corrective action or inaction at the site, she said, “We keep the report process simple and consistent. Each time you receive a report it’s the same – you can see all the elements of the site, where the tiebacks are, what the excavation grade is.”

All aspects of previous jobs are systematically catalogued, says Ford, including lessons learned.

“We’re knowledge workers as well as contractors, it’s important for our success to document and retain as much experiential knowledge as technical knowledge,” she said.

A core group of about 12 field technicians and surveyors undertake the day-to-day work on construction sites, and “we focus on keeping that team together,” Ford said, since the extensive experience of the people reading the instruments is as important as the instruments themselves to the success of any project. As well, the company provides job shadowing for new hires and ongoing training for all of its 22 employees.

Monir has been involved in monitoring projects in Western Canada, the United States and the Caribbean, says Ford, but most of its projects have been medium- to high-rise condominiums in southern Ontario, particularly in Toronto’s downtown core.

Monitoring is about mitigating risk, Ford points out, and as available sites become smaller, deeper and closer to sensitive structures, they come with their own challenges.

“We’ve seen the complexity of the scopes increase significantly over time,” she said. “That requires a higher degree of ingenuity when designing the monitoring systems and increased co-ordination on our part.”

Mitigating risk

Monitoring was an integral part of the success of the excavation support for Absolute Condominiums in Mississauga, Ont., an award-winning high-rise development whose undulating 40- and 50-storey “Marilyn Monroe” towers included six levels of underground parking. For the foundation construction, which was completed in stages to a depth of approximately 60 feet, shotcrete shoring was the most economical system for the upper weathered rock, but it had been used for very few projects of this magnitude and complexity.

To verify system performance and allow for timely adjustments during construction, Monir’s comprehensive monitoring system consisted of three borehole inclinometers, 60 precision survey targets on the adjacent high-rise buildings and more than 400 survey targets on every other individual soil nail. The monitoring program resulted in cost and time savings for the owner – and peace of mind for a cutting-edge support system.

For the RC Harris Water Treatment Plant project in 2008 in Scarborough, Ont., the contractor had to meet stringent movement criteria across an expansion joint between the building’s exterior footing and the holding tank behind it, Ford recalled, if the joint expanded too much, water could be released from the tank, which would be devastating.

“We proposed installing extenso-meters inside the tank” across that critical joint, Ford said.

Since the tank could only be decommissioned for a short 48-hour window to allow for the installation, extensive planning and co-ordination were essential. The monitoring program was expanded to include extenso-meters fixed to telescoping rods and attached to the first row of columns and the foundation wall. The gauges were remotely monitored after the tanks were re-commissioned, sending an email alert to the appropriate people if movements exceeded the allowable limits.

“It gave the design team more freedom in terms of the support systems they were going to put in place,” Ford said.

For Toronto’s Union Station revitalization and expansion project, which began in 2011 and is ongoing, a second basement needed to be added without changing the historical structure’s outward appearance. To accomplish this, the foundation columns that support the viaduct structure, which carries all train traffic and more than 250,000 daily station users, had to be cut and extended below the existing foundation.

It was critical that this complicated “dig-down” solution be monitored at all times to safeguard the public, trains and structures. Monir developed an innovative system of monitoring that included up to eight precisely located automated total stations to ensure that track movement was negligible throughout the column cutting and extension. Its specialized team of technicians and surveyors monitored target readings and correlated the data to the jacking and load-transferring processes. This strict real-time monitoring, which required an exceptionally high tolerance of 0.3 millimetre accuracy, may be the most extensive and innovative program of its kind in Canada.

Detecting early instability

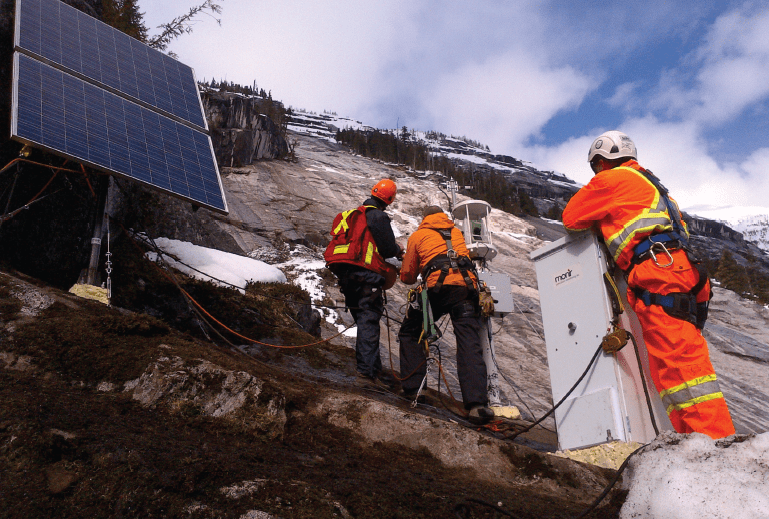

Public safety as well as worker safety is always an important consideration when selecting what type of monitoring to use, Ford says, and it can also be a project’s primary objective. In 2017, the company was hired by Alterra Power Corporation to monitor a rockslide area in the B.C. interior, where its real-time monitoring enabled crews to work safely while repairing rockslide damage to a penstock.

Since the remote location had no access to a traditional power grid and the logistics were so challenging, Ford recalls, everything was planned in minute detail in the office, then flown by plane to the site. Monir designed and built a total station monitoring system using solar power, and radios transmitted data back to the technician and a computer at the base station. Years after its installation the system continues to perform well, allowing safe access to the project infrastructure for Alterra’s operations team.

There’s an inherent risk in taking on a lean design, says Ford, and uncertainty can lead to beefing up a design to account for unsubstantiated risks. Monitoring to detect early instability and movements gives contractors and geostructural engineers alike, “a tool to complete more precise designs, which can then be verified and adjusted if necessary, providing potential savings to construction,” she said.

“There’s an element of sustainability as well,” she said, since choosing to incorporate less steel and timber in the shoring doesn’t just reduce construction costs – it also reduces the impact on natural resources. This ongoing risk mitigation also allows construction work to be undertaken in closer proximity to operating structures and utilities, and areas where earth retention was previously thought to be too costly can now be developed, says Ford.

“Monir’s experiential knowledge gives the engineers the confidence to say, ‘Okay, we’re going to try this method, we’ll reduce the pile size, we’ll economize the number of tiebacks, and we’ll watch and see how the wall is performing,’” she said, while verifying the design strength on a continual basis.