Finnish equipment manufacturer Junttan Oy recently launched a new soil compaction tool, its Rapid Impact Compaction (RIC) solution. This technology redefines soil stabilization, offering efficiency and effectiveness for construction projects worldwide.

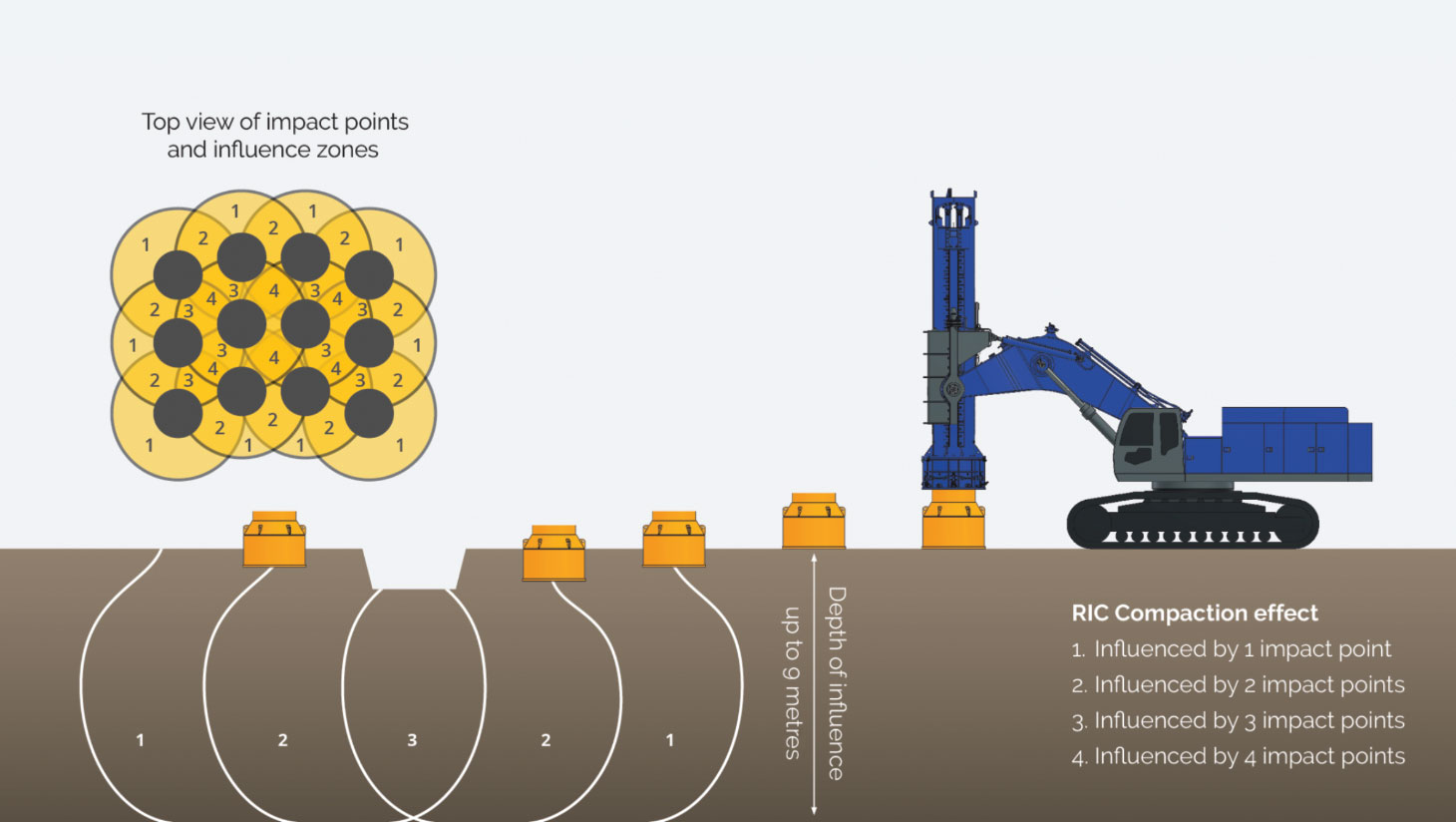

The compaction foot, attached to a hydraulic hammer, harnesses the power of rapid, high-energy impacts to deliver up to 100 blows a minute as required to densify surface layers, minimize liquefaction risk or improve the bearing capacity of specific soil types up to nine metres.

According to Michiel van Es, vice-president of sales and operations for Junttan BV, the RIC solution provides fast and efficient ground compaction.

“The RIC’s innovative design is centred around its unique, high-frequency impact system,” said van Es. “This cutting-edge technology allows it to compact soil at an unparalleled pace.”

One of the most significant advantages of Junttan’s RIC solution is its speed and efficiency. Traditional compaction methods can be time-consuming, requiring multiple passes and significant manpower. RIC, on the other hand, can complete compaction in a fraction of the time, greatly accelerating construction schedules and reducing labour costs.

Available in three models – the 9S, 16A and 16S – this impact compaction solution can be used on a wide range of soil types and conditions, making it a versatile tool for use on a variety of projects.

When and how to use the RIC tool

Junttan’s RIC solution is versatile and suitable for a wide range of soil types. Whether it’s loose sands, silts or gravels, RIC can adapt to various soil conditions.

“Soil compaction is used to densify loose granular soils and loam fill, and to prepare industrial brownfield sites for rebuilding,” said van Es. “It enables surface compaction, liquefaction mitigation and waste stabilization. It’s in high demand to improve the bearing and settlement characteristics of the top layers of a work site, especially because its depth of influence coincides perfectly with a three-by-three footing.”

“Junttan RIC’s advanced technology improves productivity and reduces project completion time.”

Michiel van Es, Junttan BV

In use, the compaction foot is installed on a hammer, then set on the ground where required. After positioning, the hammer is activated. It uses a high-frequency, controlled-energy compaction technique.

Within a frame, a drop weight is lifted to a predetermined height and dropped onto the compaction foot. The foot remains in contact with the ground while the drop weight repeats this sequence anywhere from 30 to 100 times a minute until the project’s compaction specifications are met. The operator then repositions the hammer on the next marked location and repeats the process.

“Junttan RIC’s advanced technology improves productivity and reduces project completion time, thanks to its high-speed functionality,” said van Es.

Technology reduces environmental impact

Junttan’s new RIC technology considers the ever-increasing need in the construction industry, as in all industries, for environment-friendly operations.

Compared to traditional compaction methods that often require heavy machinery and extensive fuel consumption, RIC is an environmentally friendly option. Its precision and efficiency reduce the carbon footprint associated with construction projects, aligning with the growing demand for sustainable construction practices.

“By streamlining the compaction process, the RIC significantly lowers fuel consumption and CO2 emissions,” said van Es. “It was also designed to create less noise pollution than other technologies currently in use.” ![]()

IMAGES: courtesy of Junttan Oy