Since entering the Canadian marketplace in 2005, BAUER Foundations Canada Inc. (BFCA) has established a reputation as one of the top contractors for complex foundation projects in the infrastructure, industrial, energy, mining, commercial and hydro dam sectors.

The Calgary-headquartered BFCA is a subsidiary of the German-based BAUER Group’s construction division, BAUER Spezialtiefbau GmbH – a world leader in special foundations techniques. BAUER has a solid presence in diverse industries, with engineering, construction and equipment manufacturing divisions in more than 70 countries around the world. BAUER operates a worldwide network with 110 subsidiaries that allows it to provide clients with innovative solutions and equipment.

The BAUER Group has a history spanning back to 1790 when Sebastian Bauer established a workshop in Schrobenhausen, Bavaria. In the early days, the artisan workshop focused on copper work. One of the famous historical projects performed was the copper cladding for the roof of St. Jakob’s Church tower in Schrobenhausen.

By the end of the 1800s, BAUER branched into construction, building wells and water pipes throughout Bavaria. Over the following century, BAUER built its capacity in construction and experienced significant growth during the post-war era and achieved some significant milestones. For instance, BAUER invented the first injection anchor in a construction site in Munich in 1958. Other BAUER “firsts” included the construction of the first anchor drill rig UBW01 in 1969 and the heavy-duty rotary drilling rig BG7 in 1975. By the mid-1970s, BAUER started to establish an international presence and now does work all over the globe.

Shortly after BFCA entered the Canadian marketplace, the group began construction on the Hydro-Québec’s Peribonka dam – the world’s deepest cut-off wall at the time. The team installed the 116-metre deep slurry cut-off wall in extremely challenging geotechnical conditions. “This project is a good example of BAUER’s innovation and engineering excellence,” said BFCA’s managing director, Samir Hebib. “Early on, we established ourselves as the first-choice specialist contractor for complex foundation projects throughout Canada.”

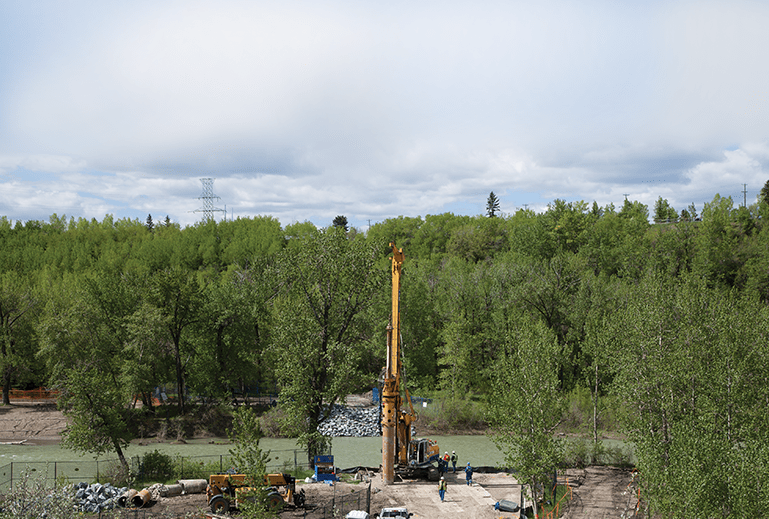

Today, BFCA has its head office in Calgary, but works on projects all over Canada. BFCA offers products in the full range of piling, shoring, slurry walls, ground improvement and grouting. BFCA is also able to draw upon additional techniques and expertise through the BAUER network, such as soil freezing and maritime drilling technology.

“We operate state-of-the-art equipment, which is manufactured in-house by our machinery division at our facilities around the world. The quality of our equipment is well recognized in the industry as many of our competitors use the BAUER equipment,” said Hebib. “Having access to such manufacturing facilities gives us a unique position in the market whereby we can manufacture or adapt equipment for specific projects.” For instance, BFCA manufactured a new cutter that reached depths of 135 metres for the Peribonka dam because the required depth of the cut-off wall was beyond the capabilities of equipment available at that time.

More recently, Diavik Diamond Mines, located in the Northwest Territories, contracted BFCA to construct a cut-off-wall system in an open-pit expansion project. To complete the project, Hebib says BFCA designed a multi-purpose “Swiss army knife rig” drill rig capable of performing drilling, cutter-soil mixing and grouting to reduce mobilization costs to this remote site.

“We can solve the most complex challenges that are thrown to us in terms of logistics, ground conditions and engineering,” said Hebib. “The project required the construction of a water retention dike in a lake to dry up a lake section for open pit mining of the A21 kimberlite pipe – a diamond-bearing rock formation. Over a period of two years, BFCA worked on this project in a remote, subarctic environment with only seasonal ice road access. The team used equipment for vibro densification, curtain grouting and rigs from the BG series for cased large diameter drilling, and the innovative cutter-soil-mixing and jet grouting to build the 1.7-kilometre long plastic concrete cut-off-wall with depths of up to 25 metres. The project was completed on time to pump out the water from the separated lake section for open pit mining.”

Closer to head office, BFCA worked on the ICE District Towers A and E in Edmonton. The team constructed 150-steel reinforced piles with lengths of up to 75 metres for the JW Marriott Hotel (Tower A) and the Stantec tower (Tower E). With 66 floors, Tower E will be Western Canada’s tallest tower. BFCA performed test piles close to 50 megapascal test load.

The team used BG40 and BG50 rigs for the job – the latter was the largest drill rig within the BAUER worldwide fleet. Although temperatures dropped to -30°C, BFCA worked 24 hours per day, six days a week until the project was completed on time and on budget. “We had the capability to install piles to over 100-metre depths had it been required by the test pile results,” said Hebib.

BFCA recently played a major role in the construction of the new Champlain Bridge that crosses the Saint Lawrence River and Saint Lawrence Seaway – a project that has been described as one of the biggest worksites in North America. BFCA constructed 200 concrete piles, with diameters of 1,300 and 2,000 millimetres and lengths ranging from 10 to 24 metres, that have been permanently cased to top of sound rock. From land or jetties, the team drilled 190 piles; another 10 marine piles were drilled from barges. BFCA completed the project on time without any safety or environmental issues. The replacement bridge is scheduled to be completed by December 2018. With more than 50 million vehicles crossing a year, the Champlain Bridge will carry the heaviest bridge-crossing traffic in Canada.

“For us, safety is our top priority. Over the last few years, we have worked on developing a safety program, a culture and values to ensure the highest levels of safety for our employees,” said Hebib. “Working across different provinces, and sometimes also in a trade union environment, creates challenges when it comes to bringing together different teams with different experiences and safety cultures.”

He cites projects such as Diavik as an example of the challenge where many multicultural teams worked together. The onus is on BFCA to communicate to each individual how systems work and how to work safely in a manner that values their own safety and their colleagues’ safety. “Aside from keeping all our employees safe, this safety record gives BFCA an advantage when it comes to tendering projects, particularly in the mining and oil and gas sectors where the safety standards are high and having good safety records is a pre-requisite for contractor prequalification,” he said.

BFCA has earned accolades for its outstanding safety record and has won the prestigious International Association of Foundation Drilling (ADSC) Safety Award for five consecutive years as well as the “ADSC Rick Marshall 2015” Award, which ADSC describes as “an award given to an ADSC member company whose commitment to providing a safe workplace is of such superior quality that it deserves special recognition above the rest.”

“BAUER’s future plans are to primarily consolidate our safety achievements,” said Hebib. “Our goal is to remain the leader in this field and – above all – make sure that we maintain a safe working environment for our employees and for others. We will also continue playing an active and leading role within the ADSC and other industry organizations to promote safety within the industry.” BFCA’s team of around 55 personnel travel to wherever they are needed for projects. In addition to being known for their outstanding safety record, the team is also known for client service.

“Providing the best service to our clients is equally important,” said Hebib. “We would like to introduce innovative solutions whenever possible to help our clients complete their projects in the most efficient manner. Stretching the boundaries of what can be done to new limits is our mission.”