At the end of May I received an invitation from Liebherr-International to attend their annual Information Tour for the International Construction Trade Press. Long time readers of Piling Canada may remember Piling Canada last attended this event in 2013 in Germany and France.

This year, the event kept things truly Canadian as tour participants found ourselves at the Liebherr-Canada Ltd. head office in Burlington, Ont. On the decision to bring roughly 60 members from the construction press sector from 15 different countries to the Canadian offices, Kristian Koch, managing direction of Liebherr-International, said, “the Canadian market offers plenty of opportunities for companies and investors from the construction and mining machinery market.”

Needless to say, I was thrilled to be invited and eager to get going. After a short flight from Winnipeg, Man., to Toronto, Ont., on Oct. 16, myself and three other tour participants hopped into a SUV and made the drive from Toronto’s Pearson International Airport to our hotel and home base for the next few days, the beautiful Queens Landing Hotel in Niagara-on-the-Lake.

Press conference

The first morning of the tour kicked off with a press conference that included presentations by Kristian Koch; Tim Petersen, managing director, Liebherr-Canada Ltd.; and Martin Schickel, managing director sales, Liebherr-France. A theme throughout Koch’s presentation was that the continued success of Liebherr is found within its almost 70-year history as a family-owned business. In fact, “the highest echelon of [Liebherr] Group consists of two members of the second and six members of the third generation,” said Koch.

Petersen took an opportunity to outline Liebherr-Canada’s operations which includes nine locations “spanning six time zones with strategically located branch offices offering reliable and cost-effective parts and service to [their] customers.” Liebherr’s continued investment in the Canadian market is justified by an increase in its gross revenue of more than 28 per cent over the past six years, with deep foundation equipment accounting for 12 per cent of total sales.

Liebherr’s REMAN program, which tour attendees would have the opportunity to witness firsthand, was a highlight of Petersen’s speech. The program re-manufactures Liebherr components in accordance with Liebherr’s high quality industrial standards; providing customers with a cost-efficient and environmentally friendly alternative to buying new products.

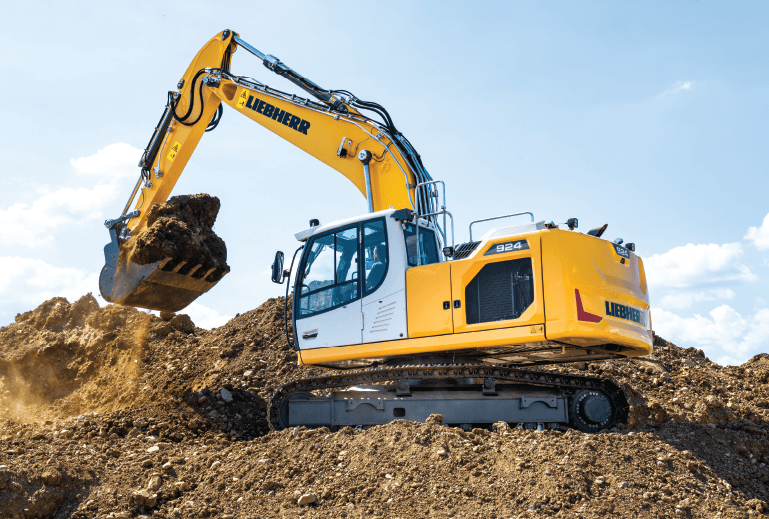

Schickel’s presentation introduced Generation 8, a new generation of crawler excavators for earthmoving. Six models will be available: R 922, R 924, R 926, R 930, R 934 and R 938. One of the innovative features of the new equipment is “a hollow moulded piece at the top of the boom,” which provides a reduced operating weight of the machine and therefore, better performance.

Liebherr-Canada head office

After the press conference, tour attendees boarded a waiting bus to transport from Niagara-on-the-Lake to Liebherr-Canada’s head office in Burlington. En route we made an impromptu stop at Niagara Falls. This was a welcome surprise for many of the international attendees who were unsure if they would have the opportunity to see the iconic Falls.

The tour of Liebherr’s Canadian head office included the recently upgraded REMAN facility. The REMAN program offers exchange components, general overhaul and repair components for Liebherr equipment. This not only has a positive impact on the environment as new materials are not constantly being sourced, it is also a cost-efficient alternative for customers to reuse and rebuild their equipment instead of buying new.

Upgrades to the Burlington REMAN facility included a special contamination free environment, component-specific assembly stations, a new state-of-the-art computer-controlled dyno, hydraulic test areas and a paint booth. All of this ensures Liebherr can maintain the highest quality control for their customers. Additional Liebherr REMAN facilities in Canada are the Mining REMAN facility in Alberta, which has been upgraded and expanded, as well as the Newfoundland branch, which is currently undergoing an expansion.

AIM Recycling

As the head office tour wrapped up, we made our way back onto the bus and drove to Hamilton, Ont., to visit American Iron & Metal (AIM) Recycling. AIM is one of the leading metal recycling facilities in the world with over 70 locations and they operate a fleet of more than 100 Liebherr material handling machines.

We were able to see two of these machines in action as one loaded the compactor and the other loaded the shredder. Due to the required elevation for both machines, each sits on a custom-built pedestal. The materials entrance for the compactor is above the height of the material handler, making the pedestal necessary for operation.

Manager of AIM Recycling Hamilton, Andrew Kummer, informed attendees that the pedestal for the shredder was required because if the shredder is not loaded just-right, it could break; operators need to have a birds-eye view to see exactly how they’re loading the machine.

Transit Projects

Day two kicked off bright and early as the tour once again boarded the bus, this time heading for downtown Toronto. I was particularly excited for this portion of the tour since we were visiting the Eglinton Crosstown LRT Project – this issue’s cover story.

It’s one thing to see pictures of the project and read about it. It’s a whole other thing to physically be there to appreciate the scope of the project. The tight quarters, other construction projects taking place, traffic flow and control, existing structures, not to mention the sheer size of the project; it’s truly an incredible undertaking. Stretching almost two hockey rinks, the future Eglinton and Yonge station is believed to be one the of the largest unpinning projects ever undertaken in Canada.

We were also able to tour the site of the future Avenue Station, which is expected to be complete in 2021. Reaching a depth of 32 metres, this will be the deepest Crosstown station. It was truly a highlight of the tour for me to stand in this massive hole and tunnel and envision the station that will be there in a few short years.

I would like to sincerely thank Liebherr-International for including myself and Piling Canada on this year’s press tour. It was a wonderful opportunity to learn more about Liebherr’s operations in Canada and abroad, and to witness Liebherr equipment in action, first hand. I’m already looking forward to the next event!