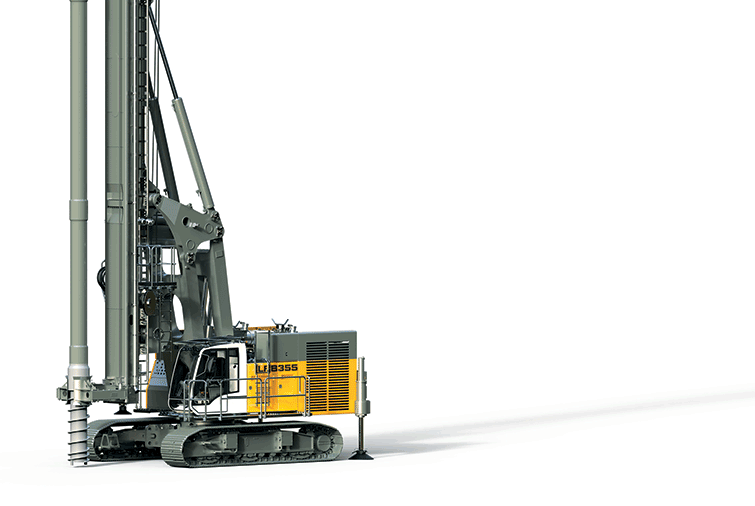

Liebherr’s new LRB 355 piling and drilling rig, first introduced this spring in Nenzing, Austria, will be available in Canada later this year through Liebherr-Canada Ltd. The latest model in Liebherr’s LRB series (for “Liebherr Ramm- und Bohrgerät,” or, in English, “Liebherr piling and drilling rig”), the LRB 355 has the series’ highest performance specifications so far, says Tobias Froehlich, marketing and communication manager at Liebherr Nenzing, and is unique in terms of performance.

“The rig’s robust undercarriage has the longest tracks in its class, which guarantees a high level of stability and low ground-bearing pressure, and the parallel kinematics offer a long outreach and thus a large operating area,” he said. The LRB 355 is available in two different configurations with a maximum height of 33.5 metres and a maximum weight of approximately 100 tonnes without attachments.

A powerful 600 kW V12 diesel engine (approximately 800 HP) drives the rig with an optional upgrade to 750 kW (1000 HP), while complying with both U.S. Tier 4 final and European emission standards. “Special consideration was paid to improving the new machine’s fuel efficiency in the design stage,” said Froehlich.

“The LRB 355 is very strong and relatively compact, packing a lot of power in a small pachage.”

Paul Sandberg, Divisional Director, Liebherr Canada

The engine runs at a reduced operating speed of 1,700 rpm and can optionally be equipped with an engine stop control that switches the rig off automatically during longer work breaks. With the optional eco-silent mode, engine speed can be reduced to a predefined level. “With this feature, a notable reduction in diesel consumption can be achieved without any impact on operational output,” he said, making it both more economical and better for the environment.

Another of the LRB 355’s optional features is the elevating working platform, which can be adjusted to various heights to enable safe and easy access to the attachments and to the rotary, making tool assembly and maintenance work easier and faster.

Easy transport and set-up

The new piling and drilling rig can be transported easily and set up quickly. The leader has a maximum length of 31.69 metres, but can be folded to a length of 20.18 metres for transportation, says Froehlich, and the whole rig can be moved with the leader, multi-sledge and rope still attached to the machine. It has a self-assembly system, so no extra tools or auxiliary crane are needed for folding the leader, mounting the counterweight or assembling the rotary drive. All winches are mounted directly on the leader, which allows the operator to see the main winch from the cab and ensures that the ropes don’t move during leader adjustment.

The LRB 355 has been designed specifically for drilling with a full displacement tool but can also be used for other drilling jobs such as double rotary-head drilling, continuous flight augering, Kelly-bored piles and soil mixing and for piling jobs using vibrator or hydraulic hammers. It offers a torque of 450 kN•m (kiloNewton•metres) and can be variably set up depending on the application, with automated torque adjustment, continuous speed optimization and four electronically adjustable speed ranges.

“Further advantages of this rotary drive are its simple structure, its low maintenance requirements and, above all, its exceptional efficiency,” said Froehlich.

Highly efficient drive system

Like all Liebherr piling and drilling rigs, the LRB 355 has been fitted with the company’s own state-of-the-art Litronic electronic control system, which has a range of programmable options for various drilling methods, and clearly displays accurate diagnostic information, including service requirements and the precise condition of the machine.

Features such as Liebherr’s data transmission and transfer system (LiDAT), simulators (LiSIM) and process data recording and reporting (PDE/PDR) are all available to help its customers increase job site efficiency. In addition, Liebherr also offers a number of different technological services. In the field of special deep foundations, these range from application consulting at the job site to simulator training and to the recording, reporting and transferring of machine-relevant data.

“The LRB 355 is very strong and relatively compact, packing a lot of power in a small package,” said Paul Sandberg, Liebherr Canada’s divisional director, who notes that a wide range of Liebherr’s products as well as parts and service are available at eleven branches throughout Canada, from British Columbia to Newfoundland. “Later this year, we are planning to add the LRB 355 to our rental fleet so that customers can try out the machine and its various applications before buying it.”