HEADQUARTERED IN CALGARY, MASTEC HAS COMPLETED PROJECTS BEYOND WESTERN CANADA IN NEWFOUNDLAND, NOVA SCOTIA AND MANITOBA, AS WELL AS SOUTH OF THE BORDER IN NORTH DAKOTA AND WYOMING

By Lisa Kopochinski

MasTec Canada may be a relatively young company, – having formed in early 2017 through the merger of six construction companies in Western Canada – but it’s already boasting an impressive array of projects in the industrial, institutional and commercial sectors across the country.

Headquartered in Calgary – with 11 field offices in B.C., Alberta and Saskatchewan – MasTec has completed projects beyond Western Canada in Newfoundland, Nova Scotia and Manitoba, as well as south of the border in North Dakota and Wyoming.

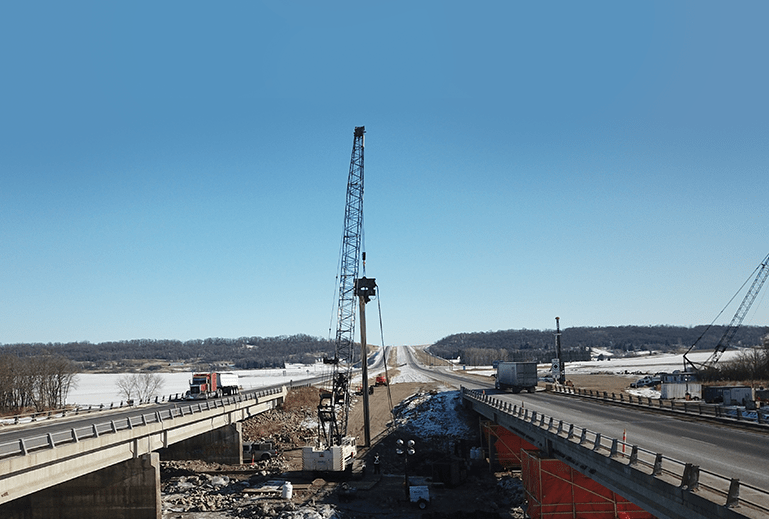

One project the company is especially proud of is the Pier Modifications for Highway Bridges over the Assiniboine River, located approximately 15 minutes east of Brandon, Man.

With a slated completion date of October, construction began in mid-January. As of late March, eight cofferdams have been installed, along with the applicable H-piles located inside each cofferdam and sheet pile extraction.

“This was to ensure all water works were completed to meet the environmental regulations regarding the provincial fish spawning restrictions/regulations and the river’s potential flood times,” said Brian Horner, MasTec’s piling general manager. “In mid-June, the project will recommence and allow for the remaining cofferdam and H-pile installations.”

MasTec’s involvement in this $10 million project includes designing the temporary cofferdams (four-sided steel sheet pile box) required for this job.

“There were 14 cofferdams in total,” said Horner. “Eight were to be designed for placement into the Assiniboine River, and six were designed for placement into the shore lines of this river. We had to design with the water force/movement/flow of the Assiniboine River in mind, as well as the hydrostatic pressure of this river. The provided geotechnical reports – along with hydrologic and hydraulic reports – also had to be taken into consideration.”

The design of the cofferdam utilized the AZ39-700 sheet piles that MasTec Canada currently owns. These thick-walled sheet piles can withstand the lateral ground pressures and the hydrostatic water pressures applied to these sheet piles/cofferdams. The design also utilized a whaler frame that consisted of HP250x85 beams, which were installed at the ground level.

“This allowed for the proper alignment of each sheet to ensure the sheets were installed at the design location,” he said. “Afterwards, the installed sheet piles were then welded to these beams. This locked in, ensuring strength and support.”

Additionally, the team had to utilize trestle beams in order to attain better access to the cofferdam locations in the river. These beams were designed in conjunction with the cofferdam. MasTec then installed additional reinforcement pipe piles, which supported these trestle’s beams.

“We installed the welded whaler beams at the ground level,” said Horner. “These beams acted as an alignment and guidance for the installation of the sheet piles as per the design requirement. After the sheets were installed, they were then welded to the whaler beams.”

Following the excavations of the cofferdams – completed by the client – MasTec installed the H-piles required to support the concrete piers, each of which was up to 47 metres long. The team welded driving shoes to each pile prior to installation. Each pile had to be welded/spliced together in order to achieve the design lengths. After the completion of the concrete works by the client, MasTec removed the sheet piles.

“All of this work was achieved utilizing our well-maintained equipment to support the piling’s activities,” said Horner. “With safety and the environment at the forefront of execution, our team bonded together to achieve this project without incident and minimization of environmental impacts. The working crews utilized MasTec Canada’s Safety Management System and Behaviour Based Observation Program. Working during the coldest part of the prairie winter (January and February), a night shift was utilized to ensure the aggressive contract schedule was met.”

MasTec used its own equipment for the project, which included the following:

165-ton Terex crawler cranes

110-ton Terex crawler crane

Delmag D30 diesel hammers

ICE 50B vibro hammer

ICE 28B vibro hammer

“We currently own the AZ39-700 sheet piles used in the design and installation of the cofferdams,” said Horner. “As a result of MasTec owning these sheet piles and having them available for this project, the design incorporated these sheets. With these sheets being a thicker and stronger size, this afforded sufficient support for the intended design. The sheets provided a capacity in excess of 1,200kN.m.”

The following companies supplied equipment:

Driven H-piles (310 × 110) – 18 metres to 47 metres in total length (supplied by Manitoba Infrastructure)

Driving shoes (310 × 110) (supplied by Manitoba Infrastructure)

AZ39 sheet piles – 50 to 60 feet in length (supplied by MasTec Canada Construction Inc.)

Whaler beams and trestles (supplied by MasTec Canada Construction Inc.)

Sheet piles – 196 pairs required; H-Piles – 168 required

Challenges

With every project, there are challenges that must be overcome. This project was no different.

“With installing sheet piles to a minimum depth of 17 metres, we mobilized vibratory and diesel hammers to ensure the design tip depth was achieved,” said Horner. “With the expectation of riprap along the river, the vibratory hammer gave greater assurance of successful installation. As a result of being able to reach into our extensive fleet of piling equipment, we were able to allocate the proper equipment to install these piles and complete this work with little to no worry of piles not reaching design embedment.”

To ensure the H-piles (up to 40 metres in length) were installed to practical refusal, driven shoes were welded onto each pile prior to installation. The Delmag D30 diesel hammers then drove these piles to practical refusal with relative ease.

“After the client built the concrete piers inside each cofferdam, the sheet piles had to be extracted,” said Horner. “MasTec Canada had to take extreme caution and care as to not damage the newly [constructed] concrete during the successful extraction of the sheet piles. We had a concern that the sheet piles would experience difficulty with the extraction process. However, with the vibro hammers utilized, this concern was ceded immediately. It was like a hot knife through butter.”

All of this had to occur with MasTec taking the necessary precautions to prevent the adjacent soils and any sort of contaminants from entering the river during the construction and removal of each associated cofferdam. No easy feat, but it was achieved.

“The underground geology and the potential of subsurface conflicts is always a prospective worry. However, with our team utilizing the correct equipment, this worry was practically jettisoned. These cofferdams were designed to take the river hydrology into account. The pressure of the river locked up the sheet piles to form a watertight seal to allow for construction work inside of each.”

When asked what the most unique aspect of this project is, Horner said, “It is working in the Assiniboine River and parallel to the existing bridges on the TransCanada Highway. The highway could not be closed, so traffic plans were created to minimize traffic impediment, yet allow the cranes to install the piles close to the bridges. With the hoisting of the piles within such close proximity, lift plans were created and followed to ensure no piles were to overhang the associated bridges.”

The river was frozen over so the design had to take the potential ice sheet impact into consideration.

“Sediments and any possible contaminants could not enter the river body. Sediment and erosion control blankets were utilized,” he said. “We are doing our part to ensure clean water ways.”