A solid, stable and safe foundation is a must have in the development of every major infrastructure to ensure their efficient, reliable and safe operation for the many years to come. Geotechnical site investigation is used as the first step to identify the properties of soil layers.

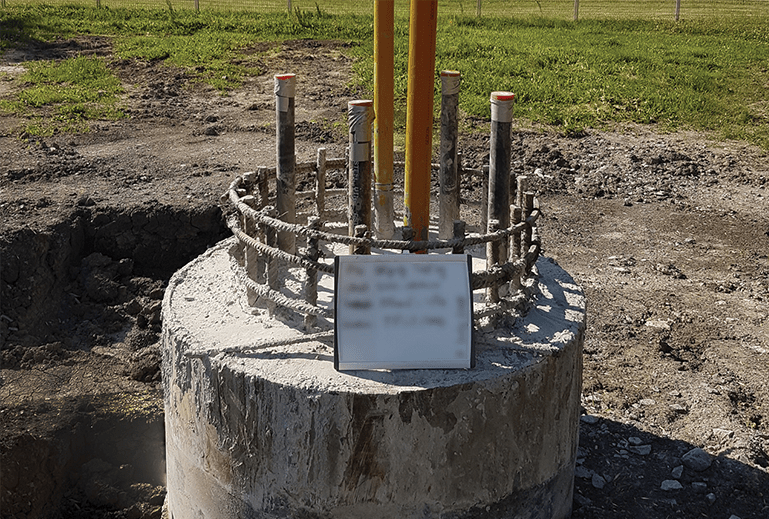

Piles and deep foundations are commonly used when the soil condition is poor. This is especially true for construction of infrastructure in coastal areas, northern permafrost and in-land deserts. Piles are used to transfer the load of heavy superstructure to the substrate. Other solutions normally involve improving and stabilizing the mechanical properties of weak soils using chemical and mechanical methods.

In order for piles to properly transfer superstructure load to the bedrock, they should be free of defects in materials and workmanship. However, construction and installation of these elements, whether they are cast-in-place piles, or driven piles, might affect the integrity of pile elements.

Such defects can be related to the consistency of pile materials (honeycombed area, segregated concrete or concrete with voids) or related to construction practice (i.e. soil inclusion, bulging, necking). Such deficiencies can directly impact load-bearing capacity of piles and contribute to partial settlement of the superstructure.

In most cases, the pile head is the only accessible area. Engineers rely on non-destructive testing (NDT) methods to evaluate the quality and integrity of piles (Rausche et al 1992). These testing techniques are used in different stages of a pile lifecycle, including:

- Quality control after construction or driving

- Routine inspection over life cycle

- Damage inspection because of major environment loading (e.g. earthquake)

- Condition assessment for seismic and structural upgrade, re-using piles in new construction, etc.

Several NDT methods have been developed to study and analyze the integrity and quality of piles. Most of these methods use ultrasonic waves to study the pile elements. Low strain impact integrity testing is a common tool for assessing concrete piles. This article will briefly discuss the concept behind the technique, and review applications and limitations of the test.

What does integrity mean?

In the context of testing piles and deep foundations, integrity refers to qualitative evaluation of the physical dimensions, continuity of a pile and consistency of the pile material. Figure 1 shows some of the most common integrity issues in piles.

Figure 1 – integrity of piles and deep foundations

How to evaluate pile integrity?

ASTM D 5882 describes the standard test procedure for testing piles and deep foundations using low-strain impact. This standard covers the procedure for determining the integrity of both vertical and inclined piles by measuring and analyzing acoustic wave velocity travel through the pile, reflected off borders and defections and recorder by a transducer attached to the pile head. The pile head is hit by a hand-held hammer usually applied axially and perpendicularly to the pile head surface. This test method can be used for slender structural members like concrete columns, poles, driven concrete piles, cast-in-place concrete piles, concrete filled steel pipe piles, timber piles, etc.

What type of deficiencies can be identified?

A pile integrity test provides acceleration or velocity information to identify potential defects in the piles. A prior knowledge about possible sources of deficiencies will be helpful in analysis and data interpretation. Like other non-destructive testing methods, the resolution of pile testing results significantly increases when site observations (e.g. soil profile, design length of pile, concrete quality, etc.) are available. The following defects can be studied using pile integrity testing:

Major cracks

These defects can affect the quality and reliability of piles. Cracks might be a result of poor construction or can be a result of damages during transportation and installation. Pile integrity can provide valuable information about the presence of such cracks in the pile. Acoustic waves are fully reflected off major crack boundaries because of high acoustic impedance between concrete and empty space. Therefore, acoustic waves provide no information regarding lower levels.

Major voids

Similar to cracks, voids can affect the consistency and quality of pile materials. Voids can affect the load bearing capacity of concrete piles as they reduce the effective cross-sectional dimension. Pile integrity testing does not provide any useful information about the portion of the pile that locates underneath the major voids or cracks.

Soil inclusion

During pouring of a drilled borehole, the hole walls slide into the hole and cause gaps over the length of pile. It is obvious there is acoustic impedance between soil and hardened concrete, but the difference is not as high as concrete and empty space. So, it is not easy to distinguish acoustic waves reflected off soil intrusion from a pile toe.

Necking

Necking in concrete piles can happen during the casting of a pile shaft in soft clay. This rapid change of cross section (as a result of necking) can be a source of an integrity problem. Necking can affect the load bearing capacity of concrete piles.

Bulging

While bulging may increase pile ultimate load, it is still considered as a pile defect and should be investigated. Pile integrity testing can effectively help identify bulging and necking in concrete piles.

Applications of pile integrity testing

Engineering analysis of pile integrity test results can reveal very useful information regarding geometry of piles and existing defects and deficiencies. The following briefly describes applications of pile integrity testing:

- Evaluate unknown length of piles or elements

- Evaluate consistency of pile material

- Determine the integrity and continuity of piles

- Evaluate pile cross-sectional area and length

- Determine pile shape as a function of depth

Limitations of pile integrity testing

This section briefly describes the limitations of pile integrity testing. These limitations must be understood for any integrity evaluation of piles:

- Pile integrity tests cannot be used for evaluation of load bearing capacity

- Pile integrity testing cannot be conducted over pile caps

- Pile integrity testing cannot provide any information of cross sections below a major crack (which crosses the entire cross-sectional area)

- This test is not effective for integrity testing of piles with highly variable cross sections

- Pile integrity testing is generally not suitable for testing steel sheets, H-section or unfilled pipe piles because the ratio of cross section/length is small

- Integrity evaluation may not be conclusive when the acoustic reflection off the pile toe is weak

- It is difficult to distinguish the soil response and the pile toe response

- Pile integrity testing cannot provide information of the durability of concrete and steel reinforcing rebar.

References:

- ACI Committee 228. “Report on Non-destructive Test Methods for Evaluation of Concrete in Structures.” ACI 228R-13, 84p.

- ASTM D5882. “Standard Test Method for Low Strain Impact Integrity Testing of Deep Foundations.” ASTM D5882 – 16.

- Rausche F., Linkins G., Kung S. R. “Pile Integrity Testing and Analysis.” Applications of Stress-Waves Theory to Piles, F.B.J. Barends (ed.), 1992 Balkema, Rotterdam. ISBN 9054100826.

Drs. Farid Moradi and Hamed Layssi are co-founders of FPrimeC Solutions Inc., a technology company in Canada. Dr. Moradi and Dr. Layssi are registered professional engineers in Québec and Ontario, respectively.

FPrimeC Solutions is a technology startup in Canada and is specialized in the design and development of innovative testing solutions for cost-effective and reliable assessment of infrastructure facilities. Their mission is to bring leading technologies and make the next generation of testing solutions.