Every industry has its blind spots.

For technology companies, it’s the failure to protect the privacy of customer data. In retail, it’s dangerous and unfair labour practices in overseas manufacturing facilities. Once identified, measures can be taken to address and eradicate a blind spot, but it often takes a tragedy before industries are moved to act.

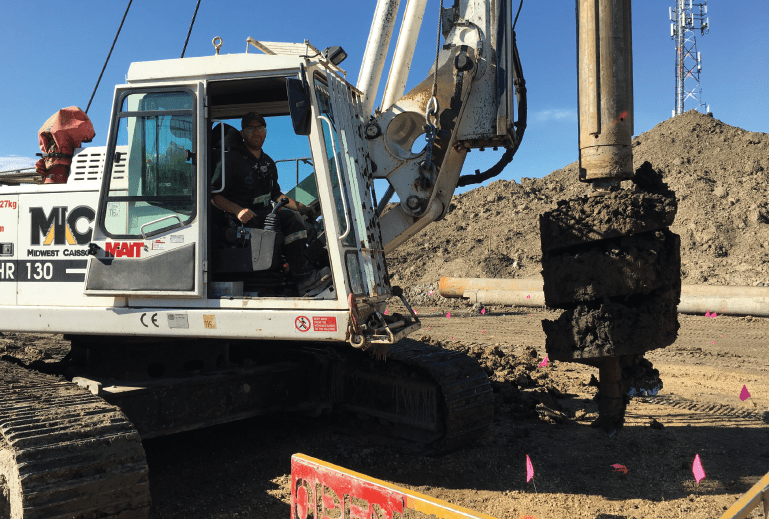

The piling industry’s long-time blind spot was arguably the absence of certified training to operate the most enormous and powerful piece of machinery on a job site: the drill rig. Although the vast majority of operators have managed to avoid catastrophe, some professionals in the business weren’t willing to stand by and wait for one to happen. Midwest Caissons, a cast-in-place piling contractor operating out of Acheson, Alta., takes safety very seriously. It had long bothered co-owners Todd Smith and Neil Sutherland that drill rig operators didn’t need special training.

“We have to have a certificate to run a skid steer or a loader and many other pieces of equipment onsite. But you take the biggest piece of machinery out there and you don’t need one. We felt we needed to be in the forefront to try and get our guys the certification they all need to do this job,” said Smith.

Sutherland points to the variables that can affect safe operations. “When it’s good clay or clay till and the drilling is good, not too much can go wrong. Unfortunately, we’re in conditions where it could be very sandy, we could get into water, boulders…you name it under there. There are lots of underground variables that make it very difficult for the operator to adapt and figure out how to install in those conditions.”

Midwest Caissons’ construction manager Andy Sneddon points to the dangers associated with the sheer size, and often awkward positioning, of the drill rig. “It’s a three-dimensional thing; you’ve got risk and potential hazards above you, hazards around you and below you. That’s what makes a drill rig unique and that’s where the need for training comes in.”

The entire company, including geotechnical engineer David Watmough and health and safety co-ordinator, estimating and HR specialist Cody Gravel, often discussed the need for better training. When Gravel got the opportunity to collaborate with the Northern Alberta Institute of Technology (NAIT) and the Western Canadian chapter of the Association of Drilled Shaft Contractors (ADSC) to help create a drill rig operator certification program, he jumped at it.

“We started out by forming a small task force that went around the industry to get support to develop a program for drill rig operators,” said Gravel.

The task force met with NAIT over two years, offering advice on the most critical components of being a drill rig operator, including practical and leadership skills. “We came up with a goal to have a certificate that’s government-approved and industry recognized,” said Gravel. NAIT began offering the two-year certification program online as a continuing education course in January 2018. It’s a first of its kind in North America. The nine online courses that make up the program include:

- Foundation Drill Rig Operator Levels I & II

- Principles of Drill Rig Operations

- Safety in Drill Rig Operations

- Introduction to Drilling Equipment

- Mechanics and Maintenance Levels I & II

- Calculations and Rigging

- Installation of Drilled Shafts

- Project Documentation/Communication/Leadership

- Blueprint Reading

“The fact that it’s online is helpful because it means people can take it remotely. A lot of times guys are working up in camps or out of town. They can do the written component from anywhere,” said Gravel.

The requirements also include a total of 1,500 hours of on-the-job experience. These hours must be monitored, recorded and signed off by a mentor and sponsor company. Potential students must have a minimum of 250 hours of experience in the construction industry in drill rig operations or a related position, a letter of support from their employer and an assigned mentor, usually a supervisor approved by the company that can vouch for their competency as a drill rig operator.

Smith says the ultimate goal of every piling company should be to have their operator(s) certified. Prior to the availability of this course, Midwest Caissons, along with most other piling companies, groomed ground team personnel to take on the responsibility over time.

“We’d typically hire someone on the ground team and develop them and coach them from that level and get them into the seat eventually, but it’s not an overnight process,” he said. “If a drill rig operator hasn’t seen varying ground conditions over the course of their crane operator employment, how do they know how to deal with issues as they come up and do it in a way that the product [pile] meets the standard required by the structural and geotechnical engineers on site?”

Since the program became available, all of Midwest Caissons drill rig operators have become certified. Smith notes that their final exam took place when they were working on a major project for which schedule was key.

“We told our client in advance that our guys were doing the practical exam on this day and needed to be off and they were all for it. Even though they lost a day of production, they knew that, in the grand scheme of things, it was important to be able to provide them an additional layer of assurance that they’re not going to have a safety issue on their site, now or in future projects. Customers care about this certification.”

NAIT informs students that they stand to gain enhanced knowledge of safety, including the ability to minimize risks, more credibility that allows employers to have increased confidence in their skills and employability and job security by providing a leg up on others who are uncertified. “If I’m looking at a resume and see that someone was driven to complete the program, it would definitely give them an advantage,” said Smith.

About Midwest Caissons

There’s a reason Midwest Caissons was keenly interested in helping to spearhead the drill rig operator certification program: a concern for safety is in its DNA. “The four core values that drive our company are safety, integrity, quality and competency. The drill rig operator program hits all of them. It made a lot of sense for us to get involved,” said Gravel.

The original company was founded by Albert and Rose Smith in 2001. When they were looking to close the business in 2014, employees Todd Smith and Sutherland incorporated as Midwest Caissons. “At that point, we focused on cast-in-place piling. Over the last five years, we’ve expanded our fleet and have ventured out into different areas such as screw piles, value engineering and pile load testing,” said Smith.

They exclusively focus on commercial projects, including recreation centres, commercial retail units, schools, hospitals and fire halls in B.C., Saskatchewan and Manitoba, although most of their work is in northern Alberta. “Predominantly our customers would be general contractors such as Clark Builders, Scott Builders, Cove Properties, Bird Construction, Carlson Construction and others who we regularly work with,” said Sutherland.

Since Smith and Sutherland took over, the number of employees has roughly doubled to 30, including eight administrative staff, five full-time drill rig operators and two relief drillers, plus a mechanic, welder and small ground team. They have six drill rigs in their fleet, one screw pile rig and static load test equipment. With Watmough’s geotechnical expertise, they do their own in-house engineering. Smith says the quality of their employees has been integral to their success and growth. Many have been with the company for 10 or more years and they experience very little turnover.

In his HR capacity at Midwest Caissons, Gravel is proud to highlight the “can-do” attitude of the business. “Everyone looks out for one another and that’s what drives the culture here. I think that is probably our greatest strength. We get a lot of repeat business and it’s because of the work we do, the guys on site and the relationships they build on the front line.”

Sutherland emphasizes the importance of developing long-term relationships with every job, whether it’s one building or 100. “If they’re building one, there’s a chance they’ll build another one day. And I think our best practice is doing the right thing the first time. We ask our guys to do their best and we support them as they do that.” As construction manager, Sneddon says it’s important to take a client’s problem and provide a solution. “We want to give them the confidence that we can execute and that includes our guys, our equipment, our in-house engineering and our ability to prove our solutions.”

Watmough says a good example of this ethos is their work on Edmonton’s Dr. Anne Anderson High School, a two-year build that required more than 800 piles and an intensive static load test. “With our customer, Clark Builders, we went through design a couple of times and we managed to decrease the size of piles by around 10 to 15 per cent. This impacted the cost, size and schedule in a very positive way.”

Gravel remembers a concerning situation that arose on that project, but the quick-thinking and planning of Midwest Caisson employees controlled the problem. “We ran into subsurface conditions that were unknown and there was methane throughout the whole site. Our guys mitigated the risk once it became apparent and we had a stand down on the site while we worked with the methane experts Clark had on hand.

“The experience our guys had and the strategy they suggested to complete the remaining 700 piles took planning and thinking. Rather than just telling the client it’s their responsibility to mitigate and we need X, Y and Z, we worked with them in collaboration in the most cost-effective way and still managed to meet the proposed timeline,” said Gravel.

Big jobs for a growing company

Among the many projects they’re proud of, they point to a few in particular that have helped them learn and grow, including a project that saw them install more than 6,000 piles for three residential buildings in Fort McMurray and a City of Edmonton sewer project for which they drilled a 12-foot-diameter hole 40 feet deep. Safety remains at the forefront of every job. As a COR-certified company, they regularly collaborate with the ADSC, including participation on a committee working to create standardization on working platforms for foundation drilling equipment.

“We’re involved with industry to try and make sure that other contractors aren’t going out and working on sites with working platforms that visually look okay, but they’re soft and could lead to the overturning or collapse of equipment. We want all workers to know they have the right to refuse unsafe work if it doesn’t look okay,” said Gravel.

On their own projects, Smith and Sneddon conduct pre-mobilizations by inspecting sites and giving advice to contractors on how to prepare the working platform so crew members aren’t at risk. When it comes to future plans, Smith says they’re looking at getting into confined space or low overhead work. “That’s where we’d like to expand. We currently offer it to a small degree, but we’d like to get into smaller equipment to get into tighter areas. These new markets would be a challenge for us and there’s a growing demand for it. People are not building new structures as much, but are instead refurbing what they have to meet their changing needs.”

Although they expect to continue to branch out into the load testing market, Sutherland says that, otherwise, they’re comfortable remaining at their current size.

For more information about the drill rig operator certification program, visit www.nait.ca/coned/foundation-drill-rig-operator.