One of which was needed on a recent project for Water Surveys Canada

Erroll Castle is accustomed to wearing many hats. Operating under the business name Castle Design & Inspection Services, he offers engineering, inspection and testing services. He also works in foundation construction and is a partner at C & E Piling Ltd.

Castle first started in construction in 2007. Recognizing a shortage of trades people in Saskatchewan at the time, he bought a trackhoe and started chasing the work. Soon afterwards Castle noticed an increasing demand for foundation construction services, particularly in the oil patch where screw piles were being used to anchor guywires.

“But a lot of those screw piles were un-engineered,” said Castle. Recognizing a potential niche where he might be able to provide added value, he sought training on screw pile design, engineering and installation from Piertech Systems in St. Louis, Mo. This training and certification process helped Castle add screw pile design and installation to his scope of practice.

According to Castle, “Any and all screw piles should be designed and checked by an engineer. There’s a lot of math that goes into it if you want it done right.”

Whether he is working on foundations for cantilevered docks, irrigation platforms or finding a way to support a new building façade on a century old foundation, Castle has a certain can-do attitude. “So much of our piling is creative solutions.”

His creative problem-solving abilities were put to use recently on a project commissioned by Water Surveys Canada, the federal agency that monitors Canada’s waterways through hydrometric monitoring. Measuring and recording hydrometric data is important to ensure that established water sharing agreements between Canada and the U.S. regarding rivers that cross the national border – such as the Red River in Manitoba or the Souris River in Saskatchewan – are being observed.

There are similar water sharing agreements in place between the federal government and the oil companies in Fort McMurray, Alta. These agreements allow for a certain portion of the Athabasca River’s water to be used by oil companies for their processing needs, while also specifying that a significant portion must remain unused and thereby preserved for nature.

Where such monitoring is required, Water Surveys Canada builds flow measuring stations: aluminum masts are installed on both banks of a river, a pair of cables is strung across the river and suspended from these cables is a sensor buoy that collects hydrometric data such as depth and cubic feet.

The spots best suited for monitoring are stretches of river that are straight for roughly a quarter mile and tend to remain relatively straight year over year.

Castle worked on a few of these projects for Water Surveys Canada in southern Saskatchewan. In each instance, the spots best suited for measuring could be easily accessed by conventional equipment. However, the most suitable site for such a station along the Athabasca River could only be accessed by helicopter.

The principal challenge was twofold: Castle had to custom-build a piling rig small enough so it could be hauled-in by helicopter, yet powerful enough that it could get the job done.

The main constraint was that the maximum weight the helicopter could carry in a single trip was 2,000 pounds. With this in mind, Castle quickly worked up and built a rudimentary first iteration. He ultimately chose to scrap his entirely unique design and opted instead to Frankenstein a miniature piling rig by sourcing existing components and cobbling them together.

“We were lucky to find a small gas-powered Ditch Witch SK350 unit with a crawler. We were lucky because these mini skid steers are hard to find. Even on the Ditch Witch website, this product isn’t very well promoted.”

Castle also experimented with different drive head sizes, ultimately settling on a suitable one from Eskridge that was about 36 inches wide and capable of 2,500-foot-pounds. A hydraulic jib also had to be built for the unit, as well as a frame-cage that would envelope the unit and to which the helicopter could attach.

Castle affectionately named the unit Spud.

In preparation for their trip to the Athabasca River, Castle and his crew first had to learn safety practices for helicopter passengers. After an initial hour-long orientation, they spent a further hour-and-a-half practising disembarking on a sandbar near Fort McMurray.

“What we had to be the most cautious about was the materials we carried. Everything had to be secured,” said Castle, “because we couldn’t risk anything flying above our heads and damaging the helicopter blades.”

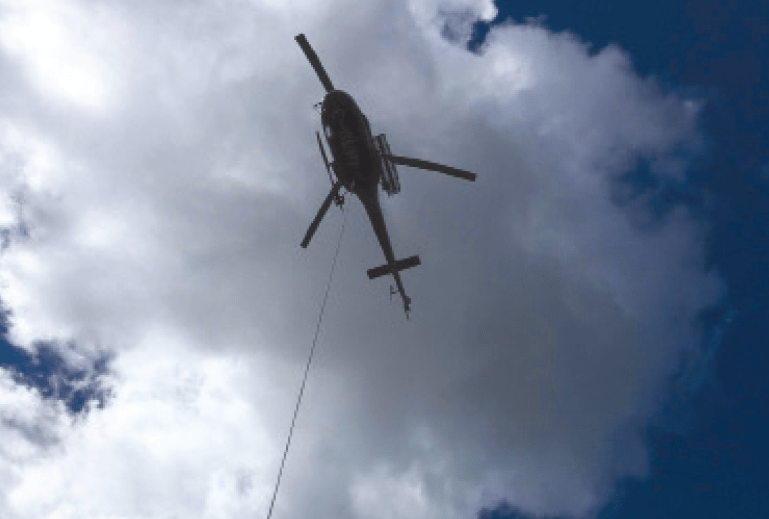

Getting to the actual site also involved several carefully planned legs. The day before the scheduled screw pile installation, a logging crew with chainsaws was sent to make a clearing to prepare a makeshift landing pad. Castle and his crew were then helicoptered in along with their equipment. Spud, the purpose-built miniature piling rig, was helicoptered in last.

Castle and his team installed four piles per shore, three in a row parallel to the river, and one just adjacent. The screw piles were made of two separate 50-inch sections bolted together to make an eight-foot-long pile, and were also custom made for this installation.

After completing one shore, Castle and his team forded the river which was about 60 feet wide and roughly three feet deep in the middle. They waded to the other bank while the helicopter flew the miniature piling rig across. This was partly done to save time. The client, Water Surveys Canada, was highly cost conscious and the rate for the helicopter was $2,000 per hour.

Careful planning and preparation for this remote installation ensured it went off without a hitch. On the day of the installation in June of 2019, “We were at the helipad in Fort McMurray at 7:30 a.m. and we were on our way home by 3 p.m.,” said Castle.

Asked what additional preparation they did for this project, Castle said, “Our testing involved playing with pitches and helix diameters. We also tested for potentially rocky conditions. We had an incomplete sense of the ground conditions we would encounter. So we had to be prepared for roots and rocks. So we did a few test piles right outside our local welding shop.”

One of the challenges that emerged during the preliminary testing was that the machine was “sensitive to pile lengths,” said Castle. “Slopes added a further degree of difficulty.

“The machine itself is finicky because it’s small.” One of Castle’s concerns was that the power in the drive head would prove to be more than the tiny Ditch Witch unit could cope with. Anticipating this possibility, Castle prepared and rehearsed a solution whereby they would guywire the unit down with a dedicated screw pile. Fortunately, the installation went smoothly and no additional measures were needed.

One of the beneficial outcomes for Castle is that he now has this unique piece of piling equipment.

“We’ve already used Spud in other jobs,” said Castle. They’ve used the mini-piling rig on a few underpinning jobs. Whereas underpinning projects are conventionally done from the outside, “Spud is compact enough that we were able to perform underpinning from the inside of a building.”

Castle is also optimistic that he’ll work on similar future projects with Water Surveys Canada, given their mandate of monitoring Canada’s waterways, and perhaps use Spud on those as well.