A major player in Scandinavia’s drilling industry sells its first rig in Canada

By Jim Timlick

Scandinavian Pile Driving (SPD) has become a major player in the foundation drilling industry in Scandinavia since the company was established by founder Magnus Andersson in 1993, and has been mentioned as one of the region’s fastest growing companies.

While SPD has made major inroads to European countries like Norway and Finland in recent years, it has remained something of an unknown entity in Canada. That is likely to change very soon. Earlier this year the company landed its first deal in this country to supply one of its DT145 EC300 drill rigs (the DT stands for drill mast telescopic) to Quebec-based Preco-MSE.

It may not register an industry-changing transaction, but sales manager Jacob Schönberg says it’s his company’s hope that the deal will help SPD establish a firm foothold in the Canadian market.

“Yeah, that’s exactly what it is,” Schönberg said when asked of the significance of the deal. “Preco is a big company in Canada and they’re well-known in the business. We hope that if they use the machine and they do a good job with it, people will look at it and say, ‘That’s a nice machine,’ and we can sell some more in Canada.”

Entering the market

SPD had been looking to break into the Canadian market for several years prior to signing a deal with Preco-MSE. The deal closed prior to the start of Bauma, the world’s largest trade fair for the construction industry that is held every three years in Munich, Germany, and where the DT145 was on display.

The two companies were a natural fit for one another. Preco-MSE already had a close working relationship with SPD’s parent company, German-based ABI Maschinefabrik, having purchased several rigs from the latter’s line of drilling systems. In fact, more than half of Preco-MSE’s $30 million fleet was manufactured by ABI.

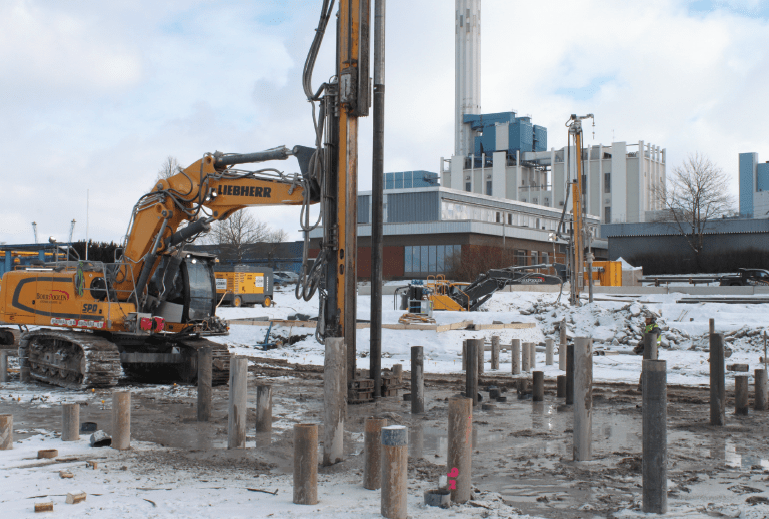

Preco-MSE CEO Marco Lessard was invited to tour SPD’s Swedish operations last year and was so impressed by what he saw, he ordered the DT145 soon after. So far, the Vaudreuil-Dorion-based company has used the unit, along with a reverse circulation system, on a handful of projects to drill piles for lagging walls that prevent soil from shifting into excavation sites.

Lessard has nothing except positive things to say about the unit’s performance.

“So far we have had very good results. Even though we had never used that kind of machine before, after a couple of days my driller was already feeling comfortable with the machine. The machine is very easy to learn (to operate). You can learn all of the functions almost by instinct,” said Lessard, whose company does more than $100 million in annual business across Canada.

One of the primary reasons Preco-MSE chose the DT145 unit, according to Lessard, was the fact it offers a completely remote-controlled operating system for both the mast and the excavator units, which he says significantly increases operator safety. It was also adaptable enough that it could be modified to incorporate a reverse circulation drilling system that collects all of the cuttings or spoils from construction sites into a single location away from pedestrians and motorists as well as features such as an automatic greasing system and a winter heating system to keep its hydraulics warm.

“Even though they are a big company in Sweden and have sold…machines all over the world, they are still listening to what their customers’ needs are and adjust. That’s what I liked from Day 1. They were sensitive to our needs,” Lessard said.

Logistical challenge

Of course, shipping a 92,000-pound piece of equipment halfway around the world poses something of a challenge. First, it had to be sent via a cargo ship from Stockholm, Sweden, to Newark, N.J. It then had to be transferred to a float trailer and driven to Montreal. All in all, the process took about three weeks to complete and it went off without a hitch.

Simple in its design and easy to use, the DT145 EC300 is one of SPD’s top selling machines and can tackle even the toughest drilling job. With a mast weight of 6,500 kilograms and measuring 15.5 metres in length with the telescopic section extended, it attaches to the boom of a Volvo EC300ENL excavator and delivers 140 kilonewtons of crowd force, making it ideal for Canada’s extremely challenging surface conditions.

“I think that’s one of the reasons we want to get into Canada is that you have pretty much the same kind of soil conditions as in Scandinavia,” Schönberg said. “This is the perfect machine for that.”

One of the more unique features of the DT145 is the 13-metre stroke that it offers, which is much longer than what most conventional drill rigs can offer.

“It will give you a 13-metre stroke and I think that was kind of a game-changer in Scandinavia,” Schönberg said. “Before that, most companies used machines with a six-metre stroke. They could only put in six metre casings one at a time. With our machine you can use a 12-metre casing. It’s much less time-consuming to make the casings with less joints.”

Remote control advantage

Another advantage of SPD’s drill rigs is that they can be controlled remotely. That means instead of being stuck in the cab, the operator can locate their self anywhere within viewing distance of the rig and can get a much better view of how the machine is operating.

“With the remote-control system, the driver gets more control over [the rig] and [they see] what’s going on all around the machine,” Schönberg said. “With the drilling, you have to be around where it actually happens. With our machine you have [the operator] outside and [they have] a remote control. [They have] a much better view of what’s going on and is also much safer.”

Over the years, SPD has earned a reputation for its attention to detail with all of the machines it manufactures. This is especially true when it comes to safeguarding the people who operate those machines.

At Bauma, SPD unveiled one of its newest innovations: replacing the safety cage around the DT145’s drill head with an infrared rotary sensor system that can shut down the machine as soon as it detects an object moving towards it. The hardware for the system can be mounted on all of the company’s machines and Schönberg says SPD is in the final stages of fine-tuning the software the system requires. The company has also adopted a system with over-centre valves that provides greater operator safety. Three-inch screens that are part of the remote-control operating system allow the operator to see the inclination of the rig, and will warn the operator if there is too much inclination.

In addition to manufacturing its own foundation mast attachments, SPD also offers a complete line of ABI rigs for a variety of piling and drilling applications through its German ownership group. It also carries a number of Swedish-built Interoc rigs including the AN150 which has been dubbed the “drilling machine of the future.” The fully remote-controlled system features a colour display, 60 per cent less hydraulic hose which reduces the risk of oil leakage, software that allows for more effective communication between its controls and hydraulics, and consumes less fuel than many rigs on the market.

Innovation has been a staple of SPD since Andersson founded the company just over 25 years ago in Sala, a small Swedish town of about 30,000 people. Andersson started his career as a mechanic before launching the company. He remains actively involved in the company’s day-to-day operations as its CEO with much of his attention focused on construction and development.

A strategic partnership

Anxious to expand his company’s reach in Europe, Andersson realized he would need some help to do so. Two years ago, he sold a majority stake in the company to ABI to form a strategic partnership with the German manufacturer. The partnership helped SPD add some of its own touches to the AN150 including its remote-control system.

“The sale was actually [Andersson’s] idea. He felt like he wanted a strong partner when going into an international venture like this,” Schönberg said. “I think it was a very good idea. It’s opened a lot of doors for us in the rest of the world. ABI is big in the foundation drilling business all over the world. It’s one of the biggest manufacturers of multifunctional rigs. When we call customers now and talk with them and tell them we’re part of ABI, they already know about ABI. It’s really helped us get a foot in the door in a lot of other countries. People notice us more now.”

Drill rigs remain an important part of SPD’s core business, but the company has branched out to other areas. It sells a full line of spare parts for all of the machines it sells, including ABI, Delmag, Eurodrill and Interoc, and has a large rental fleet for businesses in Sweden and some of its Scandinavian neighbours. They are also the Scandinavian dealer for Eurodrill products.

Despite its increasing global reach, SPD remains very much a small business at heart. Its corporate headquarters in Sala employs a staff of about 30 full-time employees with 10 office staff and another 20 in the workshop, including a handful of travelling field technicians. Andersson is quick to say much of the credit for his company’s success belongs to its employees.

“A good working environment makes the production more effective,” he told a Swedish magazine.

As for the future of SPD in Canada, Schönberg believes the recent deal with Preco-MSE is a sign of things to come.

“I think we can sell a couple of more machines there,” he said. “I think it would be a good fit. We just need to reach out to people.”