Doublestar Drilling had to mitigate some unique risks

Submitted by Doublestar Drilling

Doublestar Drilling (DSD) was awarded the Spray Lakes Slide Repair Project by Alberta Transportation in late May 2018 as prime contractor. Pre-project planning was critical to ensure all safety risk factors were discovered, and to allow for a proper and timely execution of the design.

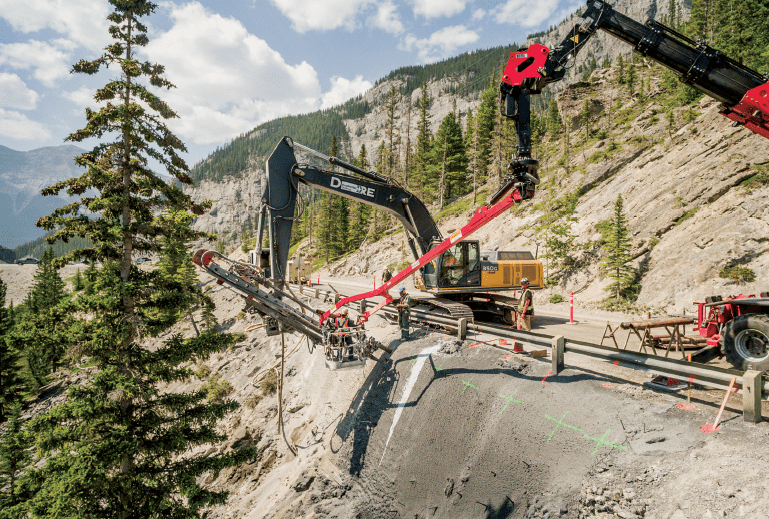

Due to the narrow job site, DSD was required to position all equipment within a five metre single lane section of the main access road from Canmore, Alta., to Spray Lakes, Alta. DSD dedicated full time flaggers to control the single lane daily traffic.

As safety is DSD’s top priority, their crews all have relevant training for working from heights as well as previous experience. Another safety concern was the risk of fallen debris since this area is a local hiking and rock-climbing spot. DSD mitigated this hazard by placing a temporary fence below the site and completing daily inspections to help ward off any climbers or hikers from entering the construction area.

Crews were equipped with DSD’s TEI HEM 1000 rock drill. The drill was mounted to a John Deere 350 excavator, allowing the rig to be positioned over the cliff while drilling. The Manitou Rotating Telehandler 2150, equipped with a specialized man basket, was used to assist changing out casing and tooling as needed.

The slide repair scope of work included installing 77 rock anchors to lengths of 16 metres, applying a 130-millimetre base layer of shotcrete and a final application of 190 mm of shotcrete to the face of the wall. The wall’s design also included proof testing each rock anchor to 133 per cent of its design load, which was up to 414 kilonewtons, and building a new guardrail along the overhang of the highway once the soil nail testing was complete.

Spray Lakes was an overall huge success and DSD takes pride in completing unique and challenging projects.