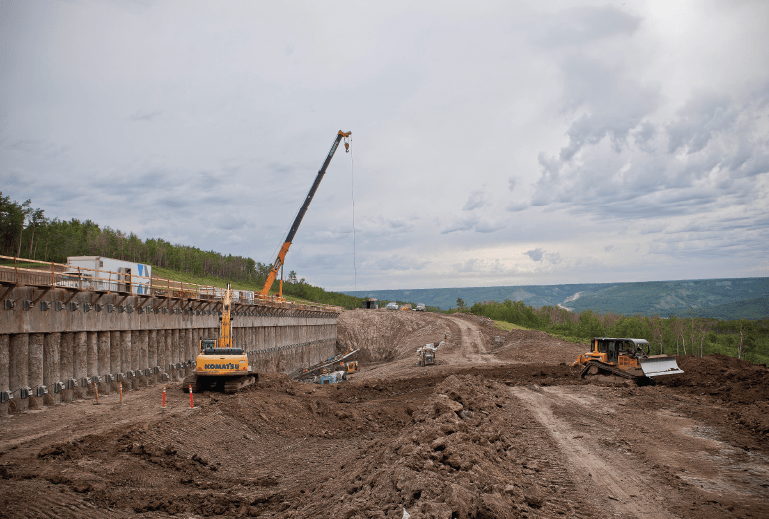

In early January 2016, Doublestar Drilling (DSD) was awarded the Daishowa – Slide Repair Tangent Pile Wall Project. The purpose of the pile wall was to permanently stabilize the slope that was failing, causing damage and the potential closure of Highway 986 North of Peace River.

DSD was responsible for installing 118 cast-in-place concrete piles, 1,200 mm in diameter, to depths of 28.5 metres. Due to soil conditions, each pile required segmental casing up to 15.0mbg to prevent sloughing and soil loss. DSD’s Liebherr LB36 and LB28 drill rigs were used to install the piles.

By the middle of March 2016, DSD completed the piling portion of the wall and began installing the deepest row of permanent DCP anchors, to a depth of 37 metres. In total, there were 354 anchors to a combined length of 11,192 metres. Solid and hollow stem auger drilling systems were required due to highly variable soil conditions on the project. Anchor rows two and three required coring through the 1,200-mm cast-in-place piles at a 30-degree angle. DSD’s two Davey Kent 725 and Soilmec SM-14 drill rigs were used to install the anchors, which were completed on schedule by the end of June 2016.

Pre-project planning and communication between project management and site personnel was essential to the success of the project due to the remoteness of the site and schedule requirements. Changing soil conditions also presented challenges for trying to maintain production when casing and/or hollow stem augers were required on over 50 per cent of the anchor boreholes.

In the end, DSD completed the tangent pile wall and DCP ground anchors on schedule and budget. The project is being highly monitored by means of shape array accelerometers (SAA), strain gauges and load cells. After one year of monitoring, the wall is performing extremely well.