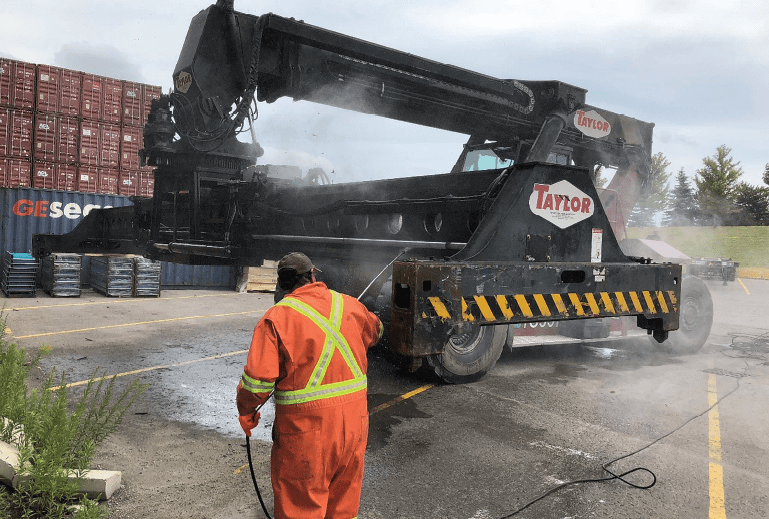

When equipment goes for servicing, mechanics and technicians will have an easier time diagnosing and fixing the problem when the equipment has been washed frequently

It’s no secret that construction is a dirty business. Perhaps none more so than deep foundation construction. After digging and drilling deep into the earth, how do contractors ensure their equipment returns to mint condition, ready for the next job? The answer lies with heavy equipment washing.

“Regular cleaning of your heavy equipment is important – not only for your company image – but also to help preserve your equipment, whether it’s for heavy duty cleaning of construction equipment, scheduled exterior maintenance to keep your fleet up to your corporate standards of image or for tackling the toughest facility, structure, restoration and graffiti removal projects,” said Michael Turner, operations manager for Metro Mobile Wash.

The company is located in Brampton, Ont., and services all of the province. It has more than 45 years of experience in providing top-notch commercial and industrial cleaning services.

“It helps to identify issues at early stages so that leaks, broken parts and rust will be taken care of and fixed before it lets you down. Additionally, a clean engine overheats less, as it’s free of dirt, grime and debris. During hot summer months, a dirty radiator on your excavator, loader or other heavy machine can put your operation to a halt unless it has been cleaned on a regular basis. In the winter, we service plenty of heavy equipment to remove salt residue,” he said.

Turner says clean equipment is, essentially, a company’s calling card.

“A lot of companies’ only advertising is the name on the equipment. Clean equipment shows pride in ownership. Also, our local law enforcement is strict when it comes to large commercial vehicles and large equipment transportation on the roads. A truck that is not well-kept is more likely to be pulled over and inspected,” he said.

Morten Merrild is one of the owners of NoviClean, a company that designs, services, sells and distributes vehicle washing equipment based in Calgary, Alta., and serves the heavy vehicle markets in Western Canada, the Canadian North and Alaska.

“We focus on environmentally sustainable, automated and manual wash system solutions for heavy vehicle fleets working in mud, sand, clay, on and off the roads of North America,” he said.

“We have had a long partnership with wash systems manufacturer, InterClean Equipment, LLC, out of Michigan to provide site-specific, engineered vehicle wash and water recycling systems for specific heavy vehicle markets. We design, supply, install and service what we sell in addition to providing preventative maintenance and bio-degradable detergent programs to our customers.”

Merrild says heavy equipment typically needs to be cleaned for two main reasons: prior to shop maintenance and to avoid cross-contamination.

“Washing is vital for mechanics to fully perform repairs and preventative maintenance on the heavy equipment. In some areas, it is important that the equipment undergoes washing after the completion of one job and before commencement of work on another site. This is to avoid any cross-contamination of soil from one site to the other. Thorough washing prevents the spread of materials, seeds, plant life and any other undesirables.”

As for how often heavy equipment should be washed, Merrild says it should be considered part of regular maintenance – not only to be completed prior to additional mechanical maintenance, but also as a standalone method to ensure complete equipment functionality.

“The frequency at which this should be completed is entirely dependent upon the conditions that the equipment is subjected to. In addition to regular, frequent washings, equipment should be fully cleaned any time there is a

concern of cross-contamination moving from one site to another,” he said.

Turner concurs and adds, “It all depends on the usage and the conditions. Tractors, trailers should all be washed on a weekly basis. Large equipment can also be washed on a weekly basis, but the norm is bi-weekly or monthly. Be aware that infrequent washing of equipment can be difficult. It could end up costing more to wash and sometimes have long-term effects on the body and frame of a truck.”

In-house washing vs. professional cleaning

As for whether machine washing can be handled in-house versus a professional business doing it, the answer is both.

“It all depends on the usage of the vehicle, the size of equipment and the quantity,” said Turner. “Small units that rarely get mud on them and/or rarely used can certainly be handled [in-house]. For anything that is time-consuming or just down-right huge and dirty, call the professionals. We (and other professional wash companies) have strong chemicals, stronger equipment and the experience and know-how to battle the toughest wash job.”

Merrild says there are pros and cons of both. For instance, handling equipment washing in-house can have significant cost savings over outsourcing washing operations.

“While the initial capital expenditure may be more significant, the equipment will last for many years and often provide cost savings within the first few years. Further, washing in-house allows the owner/operator to have total control over the frequency and intensity of the wash, as well fully customizing their wash equipment,” he said.

Conversely, outsourcing washing provides short-term benefits as the initial capital outlay is often less. However, this may be a short-term solution to an ongoing problem.

“The cost of professional washing can quickly add up and greatly exceed the cost of keeping things in-house. Organizations that prefer a hands-off approach may prefer wholly outsourcing their operations, though the costs are greater. Another concern associated with outsourcing – often found in the form of mobile steam trucks – is the difficulty in containing the water and waste after washing.”

Environmental considerations and costs

Equipment washing of any sort can be incredibly resource intensive, particularly with regards to water.

To mitigate this, Merrild says NoviClean strongly believes in water recycling. Ninety per cent of its wash-system projects sold in Canada have been installed with water-recycling systems.

“Our water-recycling systems are an integrated part of the wash bays that we build, and they deliver on-demand water of between 300 to 3,000 gallons per minute depending on customer requirements,” he said. “As part of designing wash bay systems and water recycling, we also provide the engineering design of the concrete sumps and mud managements systems to ensure systems are designed for the heavy-duty operation requirements that come with industries such as mining, construction, pipeline construction, oilfields, etc.”

He adds that many NoviClean customers have built and operate their own wash bays at their shops and maintenance facilities.

“For our customers that require a mobile, transportable wash solution, we offer transportable wash bays that are self-contained and moveable by truck,” he said.

Turner says, that while he cannot speak for other machine-washing companies, at Metro Mobile Wash, “we only wash with environmentally friendly biodegradable products. As a company, we are very environmentally conscious and are always trying out the newest, greenest products available.”

As for cost, Turner says typically most wash companies charge $100 per hour and up.

“We use a burner, water pump and a large tanker truck to wash. The cost can be per unit or hourly,” he said.

While a professional wash may be a higher cost for a company as compared to doing it in-house, the upside is often the customer gets a much higher quality wash.

“We will have the right equipment and the cost of water and chemical usage is not a concern. You won’t need an in-house employee to wash your equipment and we are available 24-hours a day, seven days a week,” said Turner.

As for the washing itself, Merrild says typically the process is an integrated wash bay system with manual wash equipment (fire hoses, stationary fire guns, power washers) or automatic wash systems (drive over chassis washes, spray arches).

“Manual and automatic can also be combined in the same wash bay for washing specialty equipment like piling/construction vehicles. An example can be a wash bay with a drive-over high-volume chassis wash followed by an open area with firehoses, power washes and foam guns. The vehicle is then driven slowly into the bay while the chassis and lower side are washed by the automatic equipment. Staff will use firehoses for manual mud removal on belts, wheels, fenders, etc. After the mud is removed, soap can be applied and the final washing will be done with power washers,” he said.

The cost of purchasing one of NoviClean’s wash systems can range from $75,000 up to $1 million depending on the size of the fleet, washing requirements, budget, etc.

“Essentially, $75,000 is for a basic manual wash system with water recycling, and $1 million if it is for a fully automatic drive-through system for extreme needs,” said Merrild.

“What is clear is that [whichever] option a customer chooses, the importance of maintaining and cleaning heavy equipment [is] of the utmost importance. The company’s success depends on it.”