The New Westminster Railway Bridge (NWRB) was originally built in 1904 to support rail, road and pedestrian traffic until it was repurposed in 1935 to operate strictly as a rail bridge. Over the years, NWRB has played an important role in supporting the greater trade and transportation network across Canada and the United States and, even today, the bridge stands tall as a critical link in the Vancouver-Lower Mainland rail network and the Asia-Pacific Gateway.

Spanning the Fraser River, NWRB connects New Westminster with Surrey in British Columbia. It is a single-track swing rail bridge that is approximately 630 metres long, with a vertical clearance of 10 metres above the water. The federal government owns NWRB but, since 1992, it has been operated and maintained by the Canadian National Railway Company (CN). In addition to CN, several other railway companies regularly use the bridge, including the Canadian Pacific Railway, BNSF Railway, Southern Railway of British Columbia, VIA Rail, Amtrak and Rocky Mountaineer.

“The workmanship that was utilized in the early 1900s to build this bridge is amazing, and the bridge has performed tremendously well under static conditions,” said Nick Lehnart, project manager at Fraser River Pile and Dredge (FRPD). “In the event of a strong earthquake, however, there was a fairly high chance the soil surrounding the foundations could liquefy, which would result in the southern piers moving horizontally and compromise the structural integrity of the bridge.”

Therefore, in 2020, CN set out to complete seismic retrofit upgrades to the bridge to ensure it could withstand earthquakes, strengthen the substructure and foundations, and reduce the amount of lateral or vertical movement during a significant seismic event.

Scope of work

Designed by Klohn Crippen Berger (KCB), the seismic upgrades called for the installation of 10 new 2,750-millimetre-diameter steel piles with 51-millimetre-thick walls – two piles each installed at Piers 6, 7, 8, 9 and 10. The piles were driven to a depth of 77 metres at their deepest. The scope of work also included the installation of a new protection pier at Pier 6, which included the demolition of the existing protection pier and driving three 73-metre, 2,750-millimetre-diameter steel piles.

According to KCB’s website, “Our solution meant that the existing foundations would continue to support the piers under static conditions, while the retrofitted piers would limit the horizontal movements of the piers and bear the weight of the bridge during and after a strong earthquake.”

To complete the work, FRPD was brought onboard in 2020 for planning and permitting, with the pile driving commencing in August 2021.

The existing bridge piers that support the superstructure of the steel spans are made of unreinforced concrete, faced with granite blocks – deep concrete caissons with a concrete-filled timber crib and timber piles embedded into the riverbed below. While the existing piles were deep foundations in name, they do not extend to the bedrock, leaving a significant depth that contains liquifiable soils that could cause settlement or movement during an earthquake.

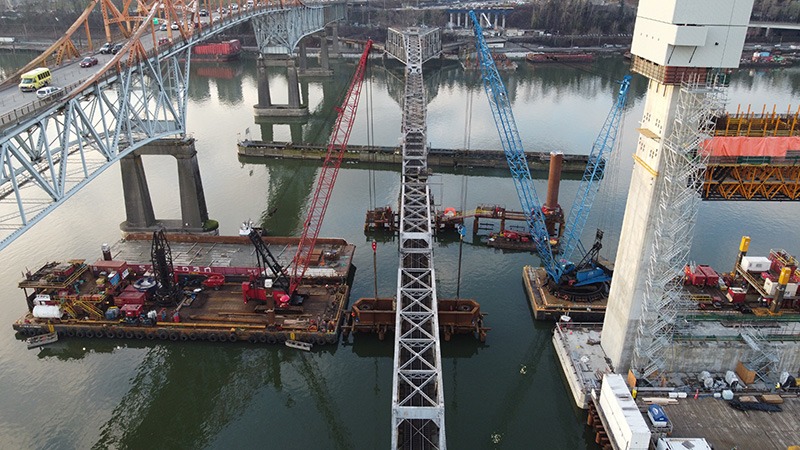

The new piles installed by FRPD were driven in welded segments from the deck of a 200 foot by 60 foot construction spud-barge, where a Manitowoc 4600 Series 5 crane did most of the heavy lifting, pile driving and operating as a base for the rest of the operation. FRPD also made use of a secondary 120 foot by 60 foot spud-barge equipped with a Liebherr HS 895 HD for the scour protection removal and replacement, falsework installation and structural steel installation.

The company used an American Piledriving Equipment (APE) Model 200-6 Vibratory Driver/Extractor to install the falsework piles and initial permanent pile segments, which was further supported by APE model D220 and D180 diesel hammers for the balance of the piling. Additionally, an APE model D30 was used for installing some of the falsework piles, depending on ground conditions. The piles are connected to the in-water piers using steel girder collars, concrete caps and post-tensioned grout pads.

A challenging project

Surrounding each pier was an unknown amount of pre-existing riprap scour protection, which was used to help stabilize the structure from erosion in the fast-moving Fraser River. Due to the uncertainty of the depth and quantity of this riprap, it proved to be a delicate balancing act for FRPD to remove enough material from each side of the pier to install the pipe, but not so much that it placed the pier in danger from scouring.

To overcome this, the company relied on historic articles and hydrographic surveys of the areas around each pier to determine the lowest point, and then used detailed current hydrographic surveys through Civil 3D to develop target designs for appropriate riprap removal around the pier.

FRPD’s Peter D Anderson derrick

“To remove the riprap scour protection, we would send our target designs to CN and their engineers for approval,” said Lehnart. “We then loaded the approved design into our real-time, GPS-equipped crane and plotted the location of each pile and its specific target riprap removal depth, allowing us to accurately remove riprap specific to where the pile needed to go. But because we were moving quite a bit of the riprap from each side, we proposed and put in three-inch clear material as a temporary scour protection so it could provide some protection around the pier, but still allow the falsework and permanent piles to be successfully driven.”

Another challenge was related to driving large diameter piles adjacent to the existing piers. For a typical project, FRPD would drive a pile segment, stack and splice the next segment, and then continue driving until depth was met. However, with the NWRB project, this would result in moving the pier outside its horizontal limits due to vibrations caused by pile driving. Due to this, the company was required to alternate between each side of the pier – driving a section on one side before moving to the other side to drive another section, then repeating this process so that the pier stayed within its horizontal tolerance.

The company relied on historic articles and hydrographic surveys of the areas around each pier to determine the lowest point, and then used detailed current hydrographic surveys through Civil 3D to develop target designs for appropriate riprap removal around the pier.

“We used a real-time monitoring system that took shots of the pier to accurately calculate movement in three axes and tell us how much the pier was moving as we drove piles. In some cases, we could finish each pile segment in full length, and at other times, we would have to stop because we would hit the threshold either for horizontal or vertical movement,” said Lehnart. “If the movement was horizontal, we would have to go around to the other side and drive the other side. If it was vertical, we would have to stop, get a track closure for up to three hours and shim the spans back to their pre-existing elevation.”

An eye on the environment

Working on the pristine waters of British Columbia and the Fraser River requires significant environmental considerations. To complete the piling and riprap removal and replacement, FRPD worked during Fisheries and Oceans Canada’s fishery window of least risk (mid-June to mid-February) and used an extensive underwater noise mitigation plan. The company also deployed multiple bubble curtain frames around the piles at different elevations, as well as an additional perimeter bubble curtain surrounding the entire pile and falseworks.

Working on the Fraser River also presents several unique construction challenges to overcome, especially as it relates to safety. Strong currents and the dangers of floating ice the in colder seasons were omnipresent, and in November 2021, flooding that impacted British Columbia’s interior resulted in considerable debris flowing into the work site.

“There are a lot of environmental hazards on this kind of job, which meant we were always monitoring the weather and river conditions, and then planning our work around those conditions,” said Lehnart. “If we saw high flows, we would move our equipment out from the centre of the river and work on piers that were a little more out of the way. We also had a number of work boats that could double as rescue boats, and all personnel on site were trained in water rescue and were required to wear a personal floatation device when working on or near the water.”

Looking back

The NWRB Replacement project required the heaviest pipe by weight ever driven by FRPD, and a project of this scale and scope, and this many different stakeholders, needed significant collaboration to successfully pull off.

“We had to be in constant communication with the different marine user groups on the Fraser River, which allowed us to obtain three-day closures to marine traffic for pile installation at Pier 6 so that we had time to stack a piece of pipe, weld it and then drive it far enough so the swing span could open,” said Lehnart. “All this had to be planned a month in advance and we’re happy to say that we hit each of those marine closures – four in total – perfectly [during] the month, and that everything worked out well. This project has been a highlight for me personally, as well as for FRPD.”