Is Toronto in the midst of a cultural renaissance? As Canada’s largest urban centre at just over 6 million people, the population has grown since 1834, overtaking Chicago to become North America’s fourth most populous city. Toronto’s longstanding institutions are undergoing massive overhauls to meet the demands of a quickly changing metropolitan area.

Built in 1894, Toronto’s Massey Hall has been the location for famous performances by artists like Bob Dylan, Lenny Kravitz, Billy Joel and Dizzy Guilespie. The venerable venue is undergoing its first major upgrade in more than a century; a seven-year, $135-million renovation at 178 Victoria Street will revitalize and improve patron amenities and offer much-needed additional backstage, administration and production space. The new six-story addition will also better the back-of-house space for performers, crew and support staff.

The project is even more forward-thinking: new space will be dedicated to educating and developing future talent and artists. These upgrades will enable Massey Hall to carry its legacy into the future and keep the space captivating and distinct for years to come.

Preserving Toronto’s heritage buildings while incorporating the city’s new developments

A brand new, 60-story luxury condominium, aptly named Massey Tower, will be constructed just to the southwest of Massey Hall. The tower will incorporate the remarkable historic features of the Canadian Imperial Bank of Commerce (CIBC) building, built circa 1905. At 197 Yonge Street, Massey Tower will preserve the breathtaking mosaics and structural columns of the old CIBC building to serve as the front façade and lobby of the new skyscraper’s main entrance onto Yonge Street.

The Massey Hall and Tower projects are actually two separate entities, with no physical connection between the two structures. Each project has different owners and investors; however, the unique challenges created by the tight quarters of the site in busy downtown Toronto required both to be constructed simultaneously. Furthermore, the owners of the Massey Tower project donated a strip of land to Massey Hall as a necessity in order to enable both the Massey Hall Revitalization and the new Massey Tower construction to take place. Neither project would have been possible without the other.

Neighboring the property to the north is the former Bank of Toronto building (built circa 1905) and to the south is Heintzman Hall, which was occupied by the famous piano company, “Heintzman & Company,” from 1912 to 1971. Additionally, to the southeast of the property is the Elgin & Winter Garden Theatre (EWG) which was built in 1913 and is a landmark of its own in the Toronto theatre community.

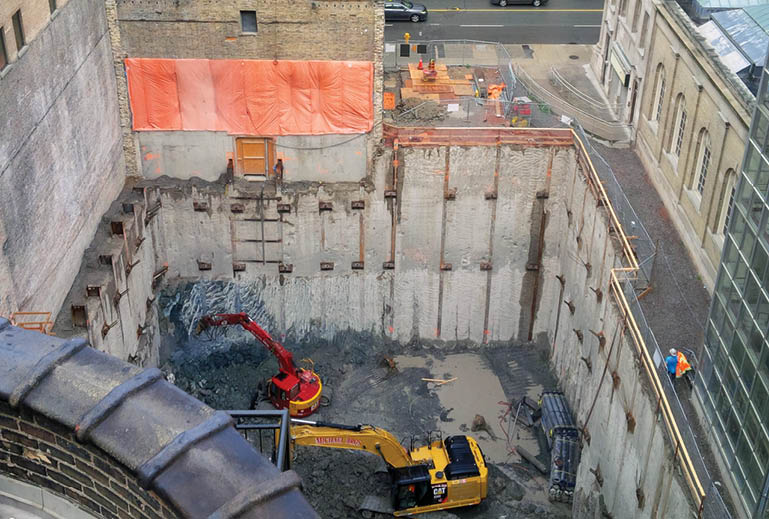

The close proximity of existing foundations and walls of these heritage buildings (each over 100 years old) – and the need to protect them – were a complicating factor for the foundation and shoring work of both projects. The new structures required foundations to be installed deeper than and very close to the footings of the adjacent heritage buildings. Due to the sensitivity of these old footings, the shoring and caisson drilling had to be completed from several different benched elevations using different equipment and techniques to suit the needs of each phase of the foundation work.

The project’s shoring and caisson foundation works were undertaken and executed under a carefully planned construction sequence by Deep Foundations Contractors Inc. (deep). deep overcame unique challenges and provided solid foundation solutions for both projects to rise as successors in the Massey Hall legacy.

The foundation works

To effectively excavate for both projects, a single shoring system connecting the two properties had to be designed. deep’s work for the projects included a secant wall shoring system, braced with soil and rock anchors, for four levels of underground facilities for Massey Tower and two levels for Massey Hall. The excavation for Massey Tower was founded in sound bedrock. The Massey Hall excavation, on the other hand, did not extend as deep, so caissons and structural piles were required to support the new structure’s loads. Massey Hall’s foundation design consisted of a combination of 28 structural shoring piles and 29 caissons, which were used to help carry the loads for the new structure to bedrock.

Maximizing real estate meant shoring walls were exceptionally close to the existing buildings. Eighty per cent of the piles on the project had to be drilled with the mast of the drill rig within inches of historic buildings. Crew and operators had to be constantly vigilant to ensure that equipment did not make contact with any of the structures or that the drilling and vibrations did not cause cave-ins or compromise any of the existing foundations.

Each of the buildings immediately surrounding the project had to have their footings exposed and located. Once the footing locations were verified, the shoring design and drilling methods were determined to match the field conditions. In many cases, the edge of the drilled hole had to be inches away from the existing foundations. In some cases, larger diameter holes needed to be drilled in order to get closer to the buildings and get the piles in their design locations. Occasionally, pile sizes had to be redesigned to suit the onsite conditions and true locations of the footings. deep’s use of conventional drilling equipment and methods gave the flexibility required to change tooling sizes on the fly and keep the job productive.

A cutting advantage: Knowing the ground you’re in

With 45 years of experience in the Toronto and Southern Ontario region, deep is extremely familiar with the soil conditions in the area and has a very well documented record of data for each block of real estate. This gave the team at deep a precise advantage: the foresight required to decide what equipment would be most effective for the needs of the project.

The Massey project sites consisted of mostly stiff to hard native silty clay till overlying shale bedrock interspersed with occasional limestone layers. The soil conditions were conducive to open hole drilling. Having the ability to drill holes open was favourable, as it allowed deep to drill without a casing, which meant holes could be drilled closer to the buildings. Even more, it was faster to change tooling for different hole diameters, and less materials were required on the job, which reduced congestion of an already tight jobsite.

Even with the complicated site configurations and challenging drill sequences, deep’s drilling and piling operations sustained no damage to any of the historical structures surrounding the sites.

Location challenges for the Massey Hall and Tower projects

In Toronto, high population density, busy city streets, local and international events, existing infrastructure, historic buildings and numerous ongoing construction projects combine, creating an abundance of challenging conditions that define Toronto’s construction industry. The coordination of the shoring, excavation and caisson foundation work for the Massey Hall and Tower projects had all of these constraints and a few more unique obstacles to contend with.

Constraints and obstacles

- The busy pedestrian and vehicular traffic on Yonge Street limited all construction access to be off of Victoria Street on the east end of the site. With streetcars passing by regularly and St. Michael’s Hospital across the road, there was no option for staging of trucks on Victoria Street. All deliveries had to be timely and had to be received into the jobsite immediately.

- The demolition of the Prince Albert Building behind Massey Hall was being undertaken concurrently with the beginning of the foundation work. As a result, the only site access off Victoria Street was limited to a 12-foot wide laneway, which made concrete and steel deliveries and movement of large drilling equipment difficult.

- Massey Hall’s existing foundations were sensitive, which limited any heavy equipment from being positioned anywhere within a 23-foot exclusion zone from the exposed walls. However, some piles had to be drilled within inches of Massey’s exterior wall. deep used an LS218 crawler crane with a Calweld drill attachment in order to reach out far enough to drill these piles while equipment maintained position outside of the exclusion zone.

- The east half of the old CIBC building was also demolished before the foundation works. This left a large excavation in the southwest end of the site, which reduced the area of the drill’s work platform and required careful planning and safe execution of the movements of the heavy equipment.

- Previously demolished buildings left the site with layers of rubble and debris 20 feet deep that had to be drilled through during installation of the shoring piles. (But the rubble was no match for deep’s Calweld crane-mounted drill.)

- The EWG Theatre and Massey Hall continued with their normal show schedules during the construction. Noise restrictions had to be followed during show times and in some cases, work had to be stopped so the shows would not be disturbed.

- The emergency egress route for EWG posed several logistical challenges for the project. The EWG building has a historic elevated fire exit projecting from the back of the structure, which acts as the only emergency egress route for the theatres more than 1,500 occupants.

The logistics of working around an emergency egress route

The Massey Tower site hosted an emergency escape that projected from the EWG. At ground level, a 12-foot-wide, fenced-off egress route had to be maintained at all times through the jobsite in case of an emergency.

A portion of the shoring wall was located directly beneath the overhanging escape route, requiring careful consideration in setting up the drilling. To install the required steel soldier piles, deep used oversized holes so that the drill mast could just clear the overhead obstacle, while the back of the drilled holes were far enough beneath the escape route so that the piles could be installed at the designed locations. The piles in this area eventually became incorporated into the supports for a temporary walkway and bridge structure crossing over the excavation between the two sites, serving as the emergency egress route as the job proceeded. Drilling of the piles below the escape route had to be done overnight while the theatre had no occupants, as the drilling obstructed the emergency egress route. deep had the capacity to run a crew at night and two crews during the day in order to accelerate the pile installation process and the project’s overall schedule.

At the same time, the excavating contractor began excavating on the west end of the site near the CIBC building in order to prepare the drill platform for the next stage of the foundation work. With the only site access off Victoria Street, work areas became very tight and constricting. This work had to be carefully orchestrated to allow for the productive and safe movement of dump trucks, concrete trucks and drill equipment.

Once the street level vertical drilling came to completion, the next steps were critical to ensure the emergency egress walkway and bridge would be in place within the required timeframe. The EWG theatre accommodated a two-week shutdown period for the initial excavation stages and temporary bridge installation. During the shutdown period the ground level escape route was removed, allowing the area to be excavated and the overhead walkway to be installed.

Several activities had to be completed during this two-week period to allow the temporary bridge to be installed. Several tiebacks for the shoring needed to be installed only nine feet below the proposed bridge location. Due to the height of the equipment, these tiebacks had to be installed quickly once the initial excavation was done and prior to the bridge being in place to avoid interference.

Meanwhile, the shoring piles at Heintzman Hall and the CIBC building had to be drilled from a lower elevation to accommodate the existing footings. This work took place at the far end of the site and access for concrete deliveries was blocked by the excavation and tiebacks being installed in the middle of the jobsite. It was necessary to complete this drilling and demobilize the drill rig before the bridge was in place, as the drill would not fit below the temporary bridge once installed. deep was able to accommodate longer shifts and weekend work in order to complete this stage of the foundation work on schedule to ensure the next stage of work on the Massey Hall and Tower projects could continue.

Excavating for the tiebacks and walkway in the middle of the site meant no access for concrete trucks to pour the secant wall in the southwest. Having all these activities occurring at the same time in such a congested area would have been a daunting endeavor for most companies. deep organized a 170-foot concrete pump to reach over the excavated jobsite from the Victoria Street entrance to pour the secant wall in the opposite corner near Yonge Street. The concrete pump solved one problem, but it also occupied the entire main entrance, blocking access for any deliveries. All activities had to be carefully scheduled and orchestrated for the work plan to be executed without disruption to any of the activities.

Once the temporary bridge was in place, access to the Massey Tower project was limited by the reduced headroom below the bridge. Nonetheless, the excavation proceeded beneath the bridge and deep’s tieback drill had to squeeze beneath the bridge to access the tiebacks for Massey Tower. Meanwhile, the vertical drilling for shoring and caissons at Massey Hall was already underway.

Protecting Massey Hall’s historic foundation

Just to the south of Massey Hall, the Prince Albert Building had been recently demolished, but its foundation walls and basement floor slab had to remain in place, connected to the Massey Hall structure, until the adjacent secant walls were installed. Heavy equipment was not allowed to enter within the footprint of the Prince Albert Building so as to not disturb Massey Hall’s existing foundation. To install the east and west shoring walls, deep used a Calweld crane-mounted drill, positioning the tracks outside the zone of influence and drilling right beside Massey Hall from over 20 feet away.

On completion of the street level drilling, the site was excavated 13 feet to the elevation of the existing footings of Massey Hall. The remaining Prince Albert Building foundations were saw-cut and removed. From this platform, the remaining shoring walls were drilled along the north and south of the site. The lowered platform provided a tight squeeze for deep’s drill rig to fit below the overhead ductwork along the exterior of Massey Hall. The Watson 3110 track-mounted rig was chosen to be short enough to fit below the ventilation ducts, while also being tall enough to hoist the piles being installed.

Working from a drill platform below street level poses its own challenges. A good functional access ramp for concrete and material deliveries is crucial. Conversely, a ramp also consumes valuable real estate, reducing the actual work area and storage space on the jobsite. All the while, access for dump trucks and equipment to the Massey Tower side of the project had to be maintained through the Massey Hall site, now with the temporary bridge overhead acting as the emergency egress route for EWG.

Due to the tight work area, semi-trailers delivering piles would have to sit on the access ramp while being offloaded by a mobile crane. Structural piles were prefabricated with nelson studs welded to both sides of the web. This required additional care when offloading, stacking and handling of these piles to prevent damage. deep had to schedule and coordinate a precise lift plan that had to be communicated and carried out by their crew to ensure safe access for the crane and deliveries, and execution of the rigging, hand signals, tagline control and laydown of the piles.

A series of interior caissons of various diameters had to be drilled from this lower elevation, as well. Most steel reinforcing cages were tied onsite in a designated area provided on the Massey Tower site. However, some of the reinforcing cages were too large to be fabricated onsite and had to be delivered individually and coordinated to arrive just before drilling of the respective caisson holes. A well-planned sequence of work had to be followed to ensure the correct steel piles and reinforcing cages were delivered on time and ready when required.

Eighty per cent of the piles on the project had to be drilled with the mast fo the drill rig within inches of historic buildings.

Summary

Both the Massey Hall and Massey Tower shoring, excavation and caisson foundation works were completed successfully and ahead of schedule. Even with the complicated site configurations and challenging drill sequences, deep’s drilling and piling operations sustained no damage to any of the historical structures surrounding the sites. In addition, the movements of the shoring system were measured and maintained within the given design tolerances, further proving the quality of deep’s shoring system. Many design challenges and logistical hurdles had to be overcome to lead to the successful completion of the foundations works for the two historic projects.

Great thanks to the geostructural engineering team at Isherwood Associates who worked alongside deep to overcome these challenges and provided effective engineering solutions. The success of both projects could not have been possible without the planning and coordination efforts of the management teams at Tucker HiRise, MOD Developments and Turner Townsend.

This article originally appeared in Foundation Drilling magazine, the official publication of ADSC: the International Association of Foundation Drilling. It is reprinted with permission.