The first article of this series covered “What is Risk?” Now we will discuss how risk and projects interact.

There are many complex models and references for geotechnical risk management from the beginning (conceptual design stage) to the end of a project (construction and operation). A proper geotechnical risk management plan has many detailed steps involved in it, such as identifying the hazards and sharing risk. Although a geotechnical investigation is just one step in the process, it is by far the most important one.

A geotechnical investigation done improperly can cause significant construction delays, increased cost overruns, redesigns and much more; ultimately and negatively impacting a project. A recent study of 41 legal court cases, where the claim was related to geotechnical issues, revealed that 55 per cent of the claims were the result of “changed soil conditions.” This type of claim is directly related to the geotechnical investigation. Other types of claims such as “design inaccuracies” may also be rooted in the geotechnical investigation. This same study also found that approximately 45 per cent of the claims against consultants were directly related to the geotechnical investigation.

What can be done to bring these numbers down? Conduct more borehole tests? Or maybe it just makes more sense to do an effective site investigation in the first place? Geotechnical unknowns usually exist in reverse correlation to the scale and quality of the investigation. We are always asked by project managers, “What is the reduction in risk for each dollar I spend on a geotechnical investigation?”

Unfortunately, the correlation between the scale of geotechnical investigation (i.e. the number of boreholes) and risk is not a universal one. Different geological regions have different soil deposits/property variability. Even for a site or region with natural variations of geotechnical conditions, different construction methods have different sensitivities to the geotechnical condition. Risk is the effect of the threats, not the threat itself. Therefore, the project affects a difference on the risk level and hence a difference on the required level of geotechnical investigation.

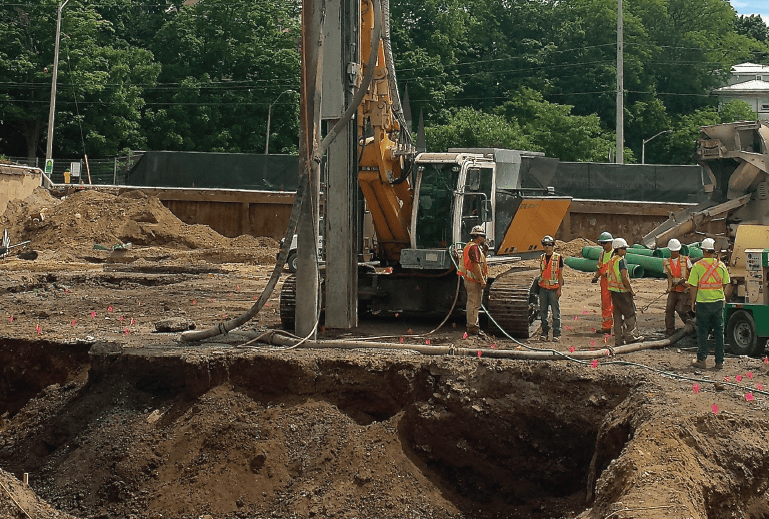

For example, an underground tunnel excavation is more sensitive than an open trench installation. Subsequently, one conducts more boreholes for a tunnel as compared to an open trench excavation. No single geotechnical investigation can function universally, but here is the good news: it is possible to arrive at an upper bound for necessary geotechnical work!

This idea started by studying cost overruns in tunnelling projects. The study shows an upper bound correlation between the ratio of total length of boreholes over tunnel length as compared to the cost overruns. The common median ratio of Borehole:Tunnel Lengths is 0.42 and there are tunnel projects with 50 per cent, or more, cost overruns when the scale of geotechnical investigation is this low and at this median BH:Tunnel Length ratio.

The same data suggests that if the number of the boreholes are increased to a ratio of 1 (Borehole:Tunnel Length), the upper estimate of possible cost overrun can be reduced to a more reasonable estimate of 15 to 20 per cent. The study also suggests there is not much benefit going beyond a Borehole:Tunnel Length ratio of 1.5.

Generally, we prefer to have this type of information in the context of the investigation cost. For major infrastructure projects, it is recommended to budget, for all phases of the geotechnical investigation, costs ranging from 1.5 to 2.2 per cent of the construction cost and have a contingency up to three per cent of construction cost (for complex conditions). For low-rise buildings, that number is as low as 0.2 to 0.4 per cent of construction costs. It is safe to say all construction projects generally sit somewhere between a low-rise building and a major infrastructure project.

The cost of an investigation is not always an accurate indication of its effectiveness. Appropriate choice of investigation methods, research on the project area (other construction, existing geotechnical information), geological modelling, quality of the investigation and a proper engineering assessment all play a key role in conducting a truly effective investigation. By employing these principles the geotechnical risk can be greatly reduced while spending the same level of money on the investigation. Don’t just spend money, do the right investigation!

Masoud Manzari is a senior geotechnical and hydrogeological engineer with over 23 years of experience and has been involved in a wide range of civil engineering projects, specifically for structures built on challenging soil sites.

Mark Tigchelaar is president and founder of GeoSolv Design/Build Inc. Tigchelaar is a licensed engineer in Ontario and Alberta, the chair of the industry Advisory Board of York University and the past chair of the Canadian Geotechnical Society-Southern Ontario section.