TEI Rock Drills in committed to quality and performance

Drilling rock is hard work. Harder still can be making the equipment that has to pass the test in the field. Since 1980, TEI Rock Drills has been passing this test thanks to winning technology, a custom approach and a “get-‘er-done” attitude born from founder Bill Patterson’s desire to do things better. Today, Patterson’s family business is a world-leading manufacturer of drilling attachments, limited access drills and drill rig components.

It all started off with single-boom underground machines and consulting services for the mining sector, says TEI Rock Drills president Sue Frank.

“When my father started the company, he was more interested in noise control for mines and was consulting to agencies like the U.S. Bureau of Mines. Then he had an idea for a new feeder system as well as a hydraulic drifter drill (TE300). He saw the benefits of hydraulic over pneumatic and so did industry. We have been growing steadily ever since.”

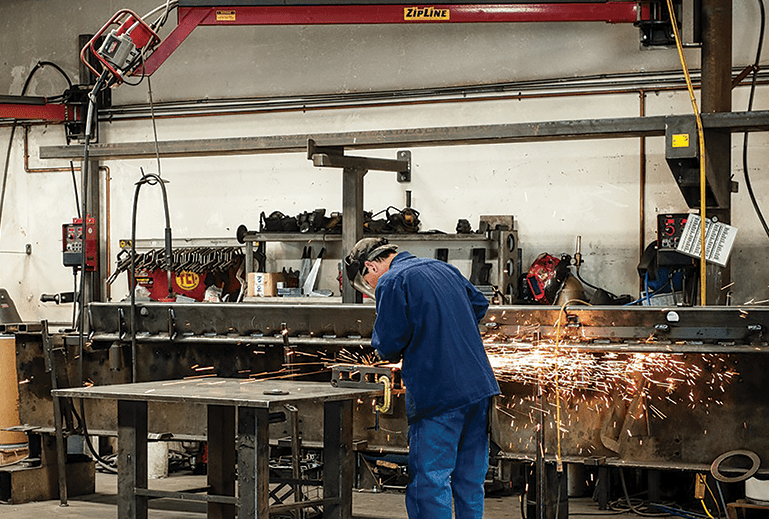

The company has been based in Montrose, Colorado since 1988 following a move from Denver. Today, TEI Rock Drills operates a 38,000-square-foot manufacturing facility and employs 24 highly skilled workers in the shop and 18 support staff in the company’s corporate head office.

Precision Machining

“Our facility is very computer-oriented and modern,” said production manager Donna Rousse. “The shop is complete and we manufacture almost everything here. We design it, we program it and we make it.” She adds that customers can expect a four- to six-week turnaround on orders. “Because we handle all the manufacturing aspects, we can be very responsive to customers that may require modifications or faster service.”

According to Frank, they have taken things to a new level with the recent ISO 9001:2008 certification. She says that a leading reason for TEI obtaining ISO certification is the ability to work directly with other manufacturers. TEI supplies drill rigs and components to OEM (original equipment manufacturer) suppliers, the United States Military and partners for special projects with contractors. “The ISO certification means that all of the parties involved are “equal” and use the same documentation method enabling the most efficient integration of all the pieces. TEI can email a print to another manufacturer and they can incorporate the print to make the initial drawings. They have the comfort of knowing that all of TEI’s processes are documented similar to their own,” said Frank, noting that the certification task was spearheaded by Rousse and took five years of commitment from the company to achieve the goal.

“We have grown a lot since I started in 1988. But now with the ISO certification we will move even further in market expansion because of the increased confidence in our consistent quality,” she said, thinking back to earlier days when the shop used manual machines rather than CNC. “Now everything is completely automated and computerized for a greater standardization and overall quality control.”

According to TEI’s vice president marketing Joe Patterson, the company does about 70 per cent of its business on the excavator side of things. In fact, the HEM Hydraulic Excavator Drill is the most popular drilling attachment manufactured at TEI Rock Drills. The stable excavator platform combined with the long boom form an excellent drilling platform.

“Part of our success is that we have patented technology that gives us an edge over our competition,” he said, commenting that TEI solely uses their patented hydraulic drifters and feed systems to build the excavator drill. These unique drifters have an internal dampening system that only allows full percussion power when the drill string is engaged.

TEI is also a leading player in limited access drills.

“We make drills that allow workers to get into places that once would have only been possible with hand equipment,” said Patterson.

He mentions a recent job where TEI teamed with GeoFirma LLC of Nashville, Tenn. The project consisted of the construction of a new, 13-mile-long by 20-inch diameter, natural gas transmission line. GeoFirma was called in to create a stable land area for the pipeline. GeoFirma called in TEI to assist with the right equipment to drill into difficult terrain.

“Our dilemma came from trying to decide on whether to have a custom-built wagon manufactured for our existing Skid Steer drill and dealing with the issues of the long hydraulic hoses and a remote hydraulic power pack, or mounting a diesel engine on the wagon and routinely changing the mounting angle of the engine to match the slope angle,” said Eric Snyder, owner of GeoFirma. The solution was found with the new TEI MT100 Mountain Drill, a drill that uses an onboard electric motor to turn the hydraulic pump.

Certified standards creat greater production consistency

“Because we handle all the manufacturing aspects, we can be very responsive to customers that may require modifications or faster service.”

– Donna Rousse, Production Manager, TEI Rock Drills

From civil work to mining, TEI is a consistent solution provider. For example, TEI’s new TE160 Hydraulic Drifter delivers Brokk Power and Safety to mines, demolition and tunneling applications. The Brokk/TEI combination eliminates fatigue caused by operating the heavy handheld tools, improves overall drilling accuracy and promotes safety by allowing operators to stand farther away from the drilling site.

“We also have new Percussion Drills in the market and in development. These represent the first new percussion drills in the last 25 years and show our commitment to innovation,” said Patterson.

Frank agrees. She says that TEI has seen good gains in the South African mining sector and is moving well in Canada where TEI is present in mining as well as civil projects such as roadwork in the Fort McMurray area.

“Now, we are expanding into Asia. This will be a big step in the next five years, but one made easier thanks to our ISO certification and our strong quality culture here,” she said, concluding that TEI Rock Drills has succeeded because of the people behind the quality. “TEI is a unique group of people who are involved and on a mission. We might be a small company, but we are achieving great things.”