First developed in the 1950s by E.A. Smith of the Raymond Pile Driving Company, the wave equation analysis of pile driving (WEAP) permitted a mathematical prediction of the drivability of piles and created a plan to ensure piles are driven efficiently and to reduce the risk of pile damage.

By creating the WEAP (pronounced ‘weep’) analysis that allowed users to calculate the various factors of a pile being driven into the ground, Smith was ahead of his time – the problem was that he was so far ahead that there wasn’t enough computing power available to run his analysis efficiently. As such, while the wave equation approach proved to be an excellent tool for analyzing impact pile driving, it took another 25 years and the personal computer revolution before Smith’s WEAP could be reliably and – more importantly – quickly calculated.

Branching out of GRL Engineers, Inc. in 1972, Cleveland, Ohio’s Pile Dynamics, Inc. (PDI) is one of the world’s largest manufacturers of industry-standard, high-quality deep foundation testing solutions. PDI’s products improve the quality assurance of deep foundations for projects in more than 100 countries around the globe.

“We were a company built on the burgeoning technologies we happened to have at the time,” said PDI vice president Ryan Allin. “In the beginning, the industry didn’t really have the ability to easily take accurate velocity and stress measurements on the pile. But once we figured out how to do that, combined with the advent of the personal computer revolution, which has allowed us to run calculations that would normally take an army of graduate students to process, that was when things really started to take off for us as a company.”

In 1976, the U.S. Federal Highway Administration funded the coding of new WEAP programs and awarded one of the contracts to GRL, which then developed GRLWEAP. The GRLWEAP program improved upon Smith’s original method with more accurate diesel hammer models and has since become one of the most used WEAP programs in the world.

“We not only build pieces of equipment and perform testing, we are actually the developers of the testing methods themselves,” said PDI founder Frank Rausche.

What does GRLWEAP do?

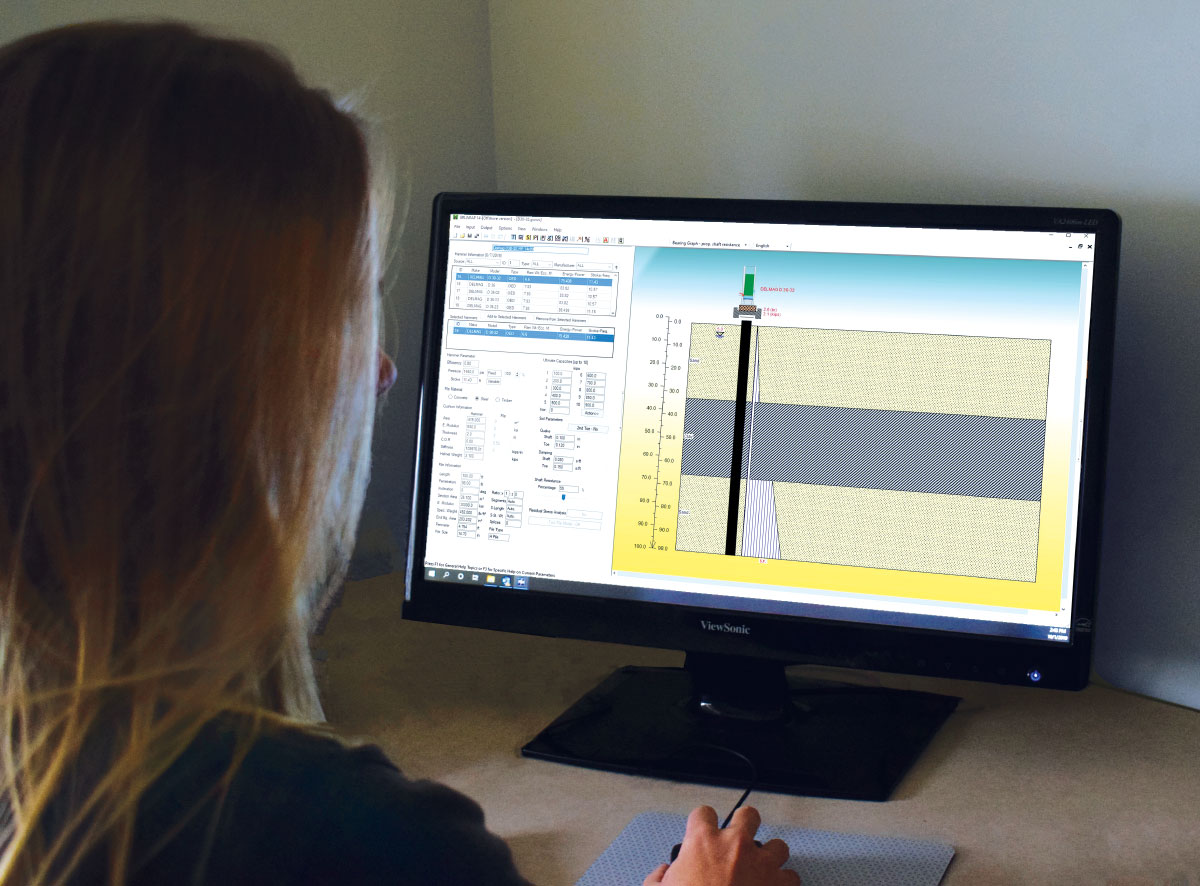

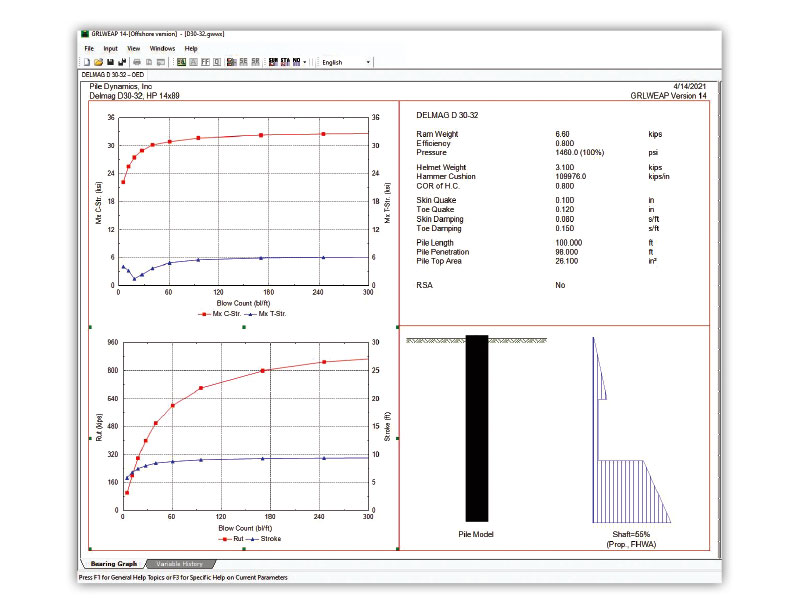

PDI’s GRLWEAP software realistically simulates the behaviour of a pile and the surrounding soil under the impact of a pile driving hammer, and powerful options combine the basic analysis of a single hammer blow into the simulation of a complete pile driving process.

“GRLWEAP is essentially a modelling software that allows a contractor to see how their hammer will perform on any given job,” said Allin. “If a contractor has a bid and has already designed the foundation and knows what the soils are, they can model the pile, model the soil, choose a hammer model and then run an analysis to determine whether that hammer is properly suited for the project. It’s a way to model the entire driving system and increase the likelihood it performs as efficiently as possible.”

GRLWEAP is an extensive program with parameters allowing the user to view a project from various perspectives. A contractor may be interested in using GRLWEAP to evaluate if their hammer will be good on a project, whereas the design engineer may want to use the software to check that the foundation is constructible as designed. Even hammer manufacturers will often have their license for the GRLWEAP software as a competitive advantage to sell their hammers and inform their customers that a particular hammer will be proper for a project.

“GRLWEAP is for anyone that wants to test if a hammer can drive a pile safely, without damaging the pile, and to the resistance needed for a project,” said Allin. “If your pile needs 200 tons of capacity and you want to see if you can use a certain hammer on this pile and get 200 tons, GRLWEAP can model that for you and either indicate that, ‘Yes, it looks like this hammer is suitable,’ or ‘No, maybe you need a bigger hammer.’”

A new GRLWEAP

For more than 50 years, PDI has continued to innovate, develop, manufacture and supply state-of-the-art quality assurance and quality control testing and monitoring, products and software for the deep foundation industry. Over time, PDI’s equipment has become increasingly modernized and efficient – its original systems filled the back of a van, where it’s now designed to fit in the palm of your hand.

In 2022, PDI released GRLWEAP14. This version of the GRLWEAP software represents a major update to the program and is the first time in GRLWEAP’s history that the original code for calculation has been rewritten. GRLWEAP14 also provides an entirely re-vamped user interface that offers a wide range of new features and capabilities yet remains familiar enough for anyone who has used earlier versions of the product.

“The upgrades we’ve added to GRLWEAP14 are just a simplification of the process and taking advantage of what computers can do for you,” said Allin. “Our clients can easily adapt to the new user interface because it’s similar to earlier software versions. This has led to a seamless adoption from our long-time existing users, who tell us they have had no problem using the new program and are enjoying all the new features.”

“If you now want to load in several different hammers for a given project into the software at once and check them all at the same time, the new GRLWEAP14 can do that.”

Ryan Allin, Pile Dynamics, Inc.

The big leap forward with the new GRLWEAP14 has been functionality, where it can now analyze multiple hammers simultaneously. GRLWEAP14 also includes 12 additional static analysis methods used to calculate soil strength, an improvement over the previous version’s four.

“We are continuously modelling new information, such as hammers or soil types, and including it into the software to ensure it remains up to date,” said Allin. “So, if you now want to load in several different hammers for a given project into the software at once and check them all at the same time, the new GRLWEAP14 can do that. This is a tremendous time saver for the user, and it ultimately leads to a more successful outcome for the piling project.”

All PDI products – including GRLWEAP14 – come with training and lifetime customer support, and the company is regularly in conversation with its clients on whatever issues they may be having.

“The client is typically reaching out because they are having trouble with a particular scenario – they’re contacting us, usually through email, and we try and troubleshoot how to handle their specific situation and model it appropriately,” said Allin. “Another of GRLWEAP’s selling features is that it falls into the whole suite of PDI testing systems. Modelling is just one half of the equation; performance testing is the other half of what we provide.”

While the underlying physics of GRLWEAP hasn’t changed, the software product is constantly being re-designed to meet the evolving needs of PDI’s customers. Because of this, the company is always looking for exciting new features that will further expand the use of GRLWEAP and make it increasingly invaluable for the end user in optimizing their foundation designs.

To see what’s new at PDI or learn more about GRLWEAP14, check out their website at www.pile.com.